Abstract

The name of this degree work is “ecological bases of wastewater leather industry”. In work it is considered types of treatment sewage water in leather industry, production technology, types of waste and methods of their cleaning. The new technology of processing of the waste of tanning, by by calcium hydroxide and sodium hydroxide combination from chromium ions(vi). Chromium is a common pollutant introduced into natural waters due to the discharge of a variety of industrial wastewaters. On the other hand, chromium based catalysts are also usually employed in various chemical processes, including selective oxidation of hydrocarbons. In all over the world, chromium (cr) is dominant in most of the effluent streams as compared to other heavy metal ions[2]. Caio f etal found that a reduction of more than 1.0 x 105 and 4.0 x 105 fold in total chromium and hexavalent chromium concentrations, respectively, was observed by employing steel wool masses as low as 0.4420 g to 30 ml solutions of wastewater [3].the optimum ph for the precipitating chromium from tannery wastewater is 7.7-8.2 with a lime concentration (2g/100ml) and the effective settling rate was 120min. The bioremoval of cr (vi) using actinomycetes is a suitable mean for reducing the tannery wastewater toxicity. The combination between the chemical precipitation and the biological removal of chromium from tanning wastewater make it meet the environment safely

Content

| Standard references……………………………………………………. | ||

| Definition……………………………………………………………… | ||

| Abbreviations…………………………………………………............. | ||

| Introduction……………………………………………………………. | ||

| Leather industry……………………………………………………….. | ||

| 2. 2.1 | Chromium in leather industry ………………………....................... Environmental considerations…………………………...................... | |

| 3. | Chromium salts……………………………………………….............. | |

| 3.1 | Chemistry of chromium……………………………………………….. | |

| 3.2 | Trivalent chromium (cr3+)……………………………………………... | |

| 4. | Environmental protection and life safety……………………………... | |

| 5. | Economic damage...…………………………………………………. | |

| The calculation of the wastewater …………………………………….. | ||

| Conclusion……………………………………………………………... | ||

| References………………………………………………………........... |

Standard references

| 1. Environmental code of the republic of Kazakhstan |

| 2. Water code of the republic of Kazakhstan |

| 3. Forest code of the republic of Kazakhstan |

| 4. State water cadastre |

| 5. Emission standards determination |

| 6. Natural resource status standards: subsoil and subsoil use, on wildlife protection, reproduction and use, as well as land, water and forest laws of the republic of Kazakhstan. |

| 7. Expert council for technical regulation |

| 8. Introduction of international standards |

| 9. Environmental labeling |

| 10. Expert council for technical regulation |

| 11. Introduction of international standards |

Definition

| 1. “Environment” means all natural and artificial objects, including air, ozone layer of the earth, surface water and groundwater, land, subsoil, flora and fauna, the climate, and the interaction there between; |

| 2. “Environmental damage” means environmental pollution or extraction of natural resources in excess of the established limits, which causes or may cause degradation and depletion of natural resources or death of living organisms; |

| 3. “Emission” means discharge or release of pollutants, industrial and consumption waste placement into the environment, and also harmful physical effects; |

| 4. “Environmental protection” means a system of governmental and social efforts to preserve and restore the environment; to prevent adverse impact, and to mitigate consequences, of economic and other activities on the environment; |

| 5. “Environmental pollution” means the presence in the environment of any pollutants, radioactive materials, industrial and consumption waste, and also the effects of noise, vibration, magnetic fields and other harmful physical effects on the environment; |

| 6. “Polluted areas” means confined areas of land surface or water bodies, which have been polluted with hazardous chemical agents in excess of the prescribed limits; |

| 7. “Habitat” means the type of region or area of natural habitation of any organism or population; |

| 8. “Natural resources” means natural resources having consumption value, namely land, subsoil, water, flora and fauna; |

| 9. “Conservation of natural resources” means a system of governmental and social efforts to protect every type of natural resources against abuse, destruction, degradation, which lead to natural resources losing their consumption value; |

| 10. “Ecological system” or “ecosystem” means an interrelated whole of organisms and their non-living habitat, which interact as a functioning whole; |

| 11. “Environmental safety” means the security of vital interests and rights of an individual, society and the state against threats arising out of man’s and nature’s impacts on the environment; |

| 12. “Environmental management” means the administrative management of environmental protection, which includes the organisational structure, planning, responsibility, methods, procedures, processes and resources for the development, introduction, implementation, analysis and sustention of the environmental policy of an enterprise; |

| 13. “Environmental monitoring” means systematic observation and assessment of the condition of, and the impact on, the environment; |

Abbreviations

Acd allergic contact dermatitis

Alm alveolar macrophage

Al action level

Apf assigned protection factor

Atsdr agency for toxic substances and disease registry

Bal bronchoalveolar lavage

Bei biological exposure index

Cca chromated copper arsenate

Ci confidence interval

Cpc chemical protective clothing

Cr chromium

Dpc diphenylcarbazide/diphenylcarbazone

Icda international chromium development association

Abbreviations

| Anova | Analysis of variance | |

| Atp | Adenosine triphosphate | |

| Dc | Direct current | |

| Dha | Dehydrogenase activity | |

| Dtpa | Diethylene triamine pentaacetic acid | |

| Dna | Deoxyribonucleicacid | |

| Era | Ecological risk assessment | |

| Gps | Global positioning system | |

| Hmn | Human | |

| Ihl | Inhalation | |

| Ipr | Intraperitoneal | |

| Int | P-iodonitrotetrazolium | |

| Ivn | Intravenous | |

| Jpeg | Joint photographic experts group | |

| Lc50 | Lethal concentration 50 percent kill | |

| Lclo | Lowest published lethal concentration | |

| Ld50 | Lethal dose 50 percent kill | |

| Ldlo | Lowest published lethal dose | |

| Lsd | Least significant difference | |

| Mus | Mouse | |

| Orl | Oral | |

| Ppm | Parts per million | |

| Rat | Rat | |

| Rbg colour spaces | Red blue and green | |

| Rna | Ribonucleicacid | |

| Tlv | Threshold limit value | |

| Ttc | Triphenyl teterazolium | |

| Twa | Time weighted average | |

| Unep | United nations environmental programme | |

| Usepa | Environnmental protection agency | |

Introduction

The actuality of the research: when an animal is alive, its skin is soft, flexible, very tough and hard wearing: it has the ability to allow water vapour to pass out, but it will not allow water in. When the skin dies it loses these characteristics: if it is kept wet it rots, and if it is dried it goes hard and brittle.

The process of tanning is to retain the skin's natural properties, to stabilise its structure and at the same time to chemically process it so it will no longer be subject to putrefecation. Thus leather is animal skin that has been treated such that its natural properties are retained.

Skin is made up of many bundles of interwoven protein fibres which are able to move in relation to one another when the skin is alive. When the skin dies, these fibres tend to shrivel and stick together. Essentially, the purpose of tanning is to permanently fix the fibres apart by chemical treatment, and to lubricate them so they can move in relation to one another.

Well tanned leather, therefore, retains the properties of flexibility, toughness and wear. It also continues to 'breathe', allowing water vapour to pass through but remaining reasonably water-proof. It is this characteristic which accounts for the comfort of genuine leather shoes and clothing.

In addition, the process of tanning imparts the advantage of resistance to heat. This is an important factor in many of the uses of leather. In conjunction with chemical processing, the tanner imparts colour, texture and finish to the leather, to enhance its appearance and suit it to today's fashion requirements.

Use of chemical compounds for chrome treatment is not a new phenomenon. A study conducted by m. Ali awan et al., 2003 identified three aqueous oxidants, namely; hydrogen peroxide, sodium hypochlorite and calcium hypochlorite independently in oxidizing chromium (iii) containing tannery wastewaters to soluble chromate (cro42-) under alkaline conditions. Among those, hydrogen peroxide was potentially a suitable oxidant as it could recover chromate (cro42-) up to 98% (from synthetic cr3+ solution) and 88% (from effluent i). Despite the different experimental conditions (temperatures and oxidation time) for all the three oxidants complete (100%) recovery could not be achieved. The recovery of chromium could help in reducing the possibility of oxidizing cr iii to cr vi (carcinogenic) compound and helps to rescue the financial and environmental cost occurred as a result of its discharge [4]. Other kinds of methods like combined system have to be also tested since it might improve the efficiency of recovering chromium from tanning process. In fact experimental conditions like, temperature, ph, time, need to be controlled to have more efficient recovery.

Chromium is a common pollutant introduced into natural waters due to the discharge of a variety of industrial wastewaters. On the other hand, chromium based catalysts are also usually employed in various chemical processes, including selective oxidation of hydrocarbons. In all over the world, chromium (cr) is dominant in most of the effluent streams as compared to other heavy metal ions[2]. Caio f etal found that a reduction of more than 1.0 x 105 and 4.0 x 105 fold in total chromium and hexavalent chromium concentrations, respectively, was observed by employing steel wool masses as low as 0.4420 g to 30 ml solutions of wastewater [3].the optimum ph for the precipitating chromium from tannery wastewater is 7.7-8.2 with a lime concentration (2g/100ml) and the effective settling rate was 120min. The bioremoval of cr (vi) using actinomycetes is a suitable mean for reducing the tannery wastewater toxicity. The combination between the chemical precipitation and the biological removal of chromium from tanning wastewater make it meet the environment safely [4].the percent removal of metal ions increases to about 99 % with increasing the mgo dose to some limits. The optimum values of mgo doses were found to be 1.5-3.0 g/l. The ph value ranges are 9.5 to 10 with mgo precipitant and ph of 11.5 to 12 with cao precipitant [5][6]. Combinations of ferric chloride and polymer at different ratio will also results in better removal efficiencies of the metals in the range 84 - 97% for total chromium, 69-90% for zinc and 6972% for total iron, also less sludge was produced [7]. There are many factors which affect the efficiency of precipitation (ph, nature and concentration of hazardous substances in water, precipitant dosage, temperature, water balance etc.,). In practice, the optimum precipitant and dosage for a particular application are determined by a “trial and errof’ approach using jar test [8]. Moreover ferrous sulphate requires ph =1for complete reduction as compared to sodium metabisulphite which requires a ph of about

A wide range of physical and chemical processes are available for the removal of cr (vi) from effluents. A major drawback with those treatment systems is sludge production, and, high operational cost and some of them are complicated for management. This actually makes the application of these technologies to be limited only in developed countries. In response to this challenge a different attempt were undertaken to produce a media which was feasible and cost effective to use by the majority. A research was done s. M. Nomanbhay and k. Palanisamy, 2005 by preparing a new composite bio sorbent which has been done by coating chitosan onto acid treated oil palm shell charcoal (ccab). It is an attractive option because of its cost effective treatment system. Among other low cost absorbent identified chitosan has the highest sorption capacity for several metal ions including chrome. Chromium adsorption was influenced by initial ph, agitation, dose of adsorbent and contact time. For instance at a ph of 5 the media managed to treat 92 % of chromium, which is significant. Further control of these environmental conditions in the laboratory may improve its treatment capacity [5].

A comparison study also conducted by leaching raw tannery effluent through mono and mixed columns (different grades) of vermiculite to evaluate their removal efficiency of chromium. The mixed column of vermicu- lite has the highest chromium removal (74.6%) while the mono vermiculite achieved 63.6%. This improvement in chrome removal efficiency is brought by the use of combined medias which increase its adsorption capacity. It was also found out that, it could remove cat ions like ca, na, mg and k. Of course high cat ion exchange helps to make the system more efficient [6].

The aim of the research – work out new methods of treatment water from ion chrome. The results obtained for industrial wastewater after the treatment using sodium hydroxide and calcium hydroxide combination are in par with the synthetic sample results. The sodium hydroxide and calcium hydroxide combination shows the better removal efficiency with less volume of sludge compared to other precipitating agents. Experiments on industrial wastewater show that, removal efficiency is in par with the efficiency obtained for synthetic sample experiments, except for ferric chloride. The cr(iii) removal efficiency using calcium hydroxide and sodium hydroxide combination was found to be 99.7% and with volume of sludge produced as 7 ml/l. On this basis one can conclude that one of chemical promising development in the chemical industry grown.

The object of course work is purification of sewage water from cr (vi) in leather industry.

The subject of the course work is deep sewage treatment conventional chrome tanning in leather production for the purpose of turnaround water supply.

Leather industry

Animal skin that has been processed to retain its flexibility, toughness, and waterproof nature is known as leather, and the leather industry is new zealand's seventh largest industry. New zealand leather is made by processing the skins of animals slaughtered in the meat processing industry, and hence the majority of skins tanned are those of sheep and cattle. Animal skins are converted to leather in an eight step process as follows:

Step 1 - unhairing

The animal skins are steeped in an alkali solution that breaks down the structure of the hair at its weakest point (the root) and so removes the hair.

Step 2 - liming

The hairless skin is immersed in a solution of alkali and sulphide to complete the removal of the hair and to alter the properties of the skin protein (collagen). The collagen becomes chemically modified and swells, leaving a more open structure.

Step 3 - deliming and bateing

The skin structure is then opened further by treatment with enzymes, and further unwanted material is removed.

Step 4 - pickling

The skins are then treated with acid to preserve them for up to two years

Step 5 - tanning

This is the most chemically complex step. During tanning, the skin structure is stabilised in its open form by replacing some of the collagen with complex ions of chromium. Depending on the compounds used, the colour and texture of the leather changes. When leather has been tanned it is able to 'breathe' and to withstand 100oc boiling water, as well as being much more flexible than an untreated dead skin.

Step 6 - neutralising, dyeing and fat liquoring

The leather is then treated with alkali to neutralise it and so prevent deteroration, and then dyed. This involves fixing a variety of compounds onto the chromium, as that is the most reactive site present. Once the leather is dyed, it is treated with reactive oils that attach themselves to the fibrous structure, improving suppleness and flexibility.

Step 7 - drying

Water is removed from the leather, and its chemical properties stabilised.

Step 8 - finishing

A surface coating is applied to ensure an even colour and texture, and to improve its ability to wear. Suede leather is also buffed at this point to give it its distinctive finish.

Animal skins that are processed in new zealand go on to be made into a variety of leather goods, or are exported in an unfinished condition to be further treated overseas.

|

Figure 2. Fundamental structure of a peptide

The main amino acid components of skin are given in table 1.

|

The basic component of the skin is collagen, a fibrous protein. The latest research indicates that the basic collagen structure consists of twined triple units of peptide chains of differing lengths. The amino acid residues are joined together by peptide links. The peptide chains within the triple helices are held together by hydrogen bonding (figure 1).

There has been no conclusive evidence showing that the amino acid residues are arranged in any particular order within the peptide chain.

Skin collagen is usually associated with keratin (the protein in hair, wool and nails). Most mammals have an outer coat of hair, wool or fur, which acts as an insulating layer and keeps the animal warm. Keratin is a fibrous protein and different from collagen in one very important aspect: the polypeptide chains are linked together by cystine linkages.

The sulphur-sulphur linkage in cysteine is susceptible to the action of alkali, and breaks down quite readily in the presence of alkali and a reducing agent.

|

The early part of leather production is the removal of hair from the skin, and the presence of the cystine linkage makes it possible physically, the skin consists of tiny interwoven collagen fibres, each of which in its turn is made up of tiny fibrils. The tanner aims to separate these fibres, remove any unwanted matter from the structure and stabilise and preserve it, whilst retaining the useful properties.for this to be acheived.

Figure 3.The peptide chains within the triple helices are held together by hydrogen

Raw materials

The basic raw material for the new zealand tanning industry is a by-product of the meat processing industry. Approximately 25 million lambskins, 8 million sheepskins, 2.2 million cattle hides, 1.2 million calfskins, 200 000 goat skins and 400 000 deerskins are available each year for processing into finished leather products. Cattle hides give leather for shoes (soles and uppers), clothing, belts and upholstery. Calfskins are used for fashionable shoe uppers, gloves and for clothing leathers. Sheepskins and lambskins with wool on are used for car seats, floor rugs, clothing, bedding and footwear, while, with the wool removed, they are used to produce suede and grain clothing leathers as well as chamois leathers.

The tanning materials used in the conversion of skin to leather are mostly imported. There are four main types:

Vegetable - extracts from the bark and wood of trees (oak, wattle etc.).

• Mineral - in the main, trivalent chromium sulphate. This is produced by the reduction of hexavalent chromium in the form of sodium chromate or dichromate by organic or inorganic reducing agents.

• Aldehydes - formaldehyde, glutaraldehyde or oxazolidine v-animal products-c-leather-4

Synthetic replacements for the vegetable tanning materials.

The treatment process - preparation for tanning

The main processing sequences of leather manufacture are shown in figure 2. Where skins are processed with the hair or wool on, the unhairing and liming processes are omitted and replaced by a scouring (washing) of the wool or hair. The main chemical processes carried out by the tanner are the unhairing, liming, tanning, neutralising and dyeing.

Step 1 - unhairing

The keratin of hair and wool is subject to attack by alkali, which will break (by hydrolysis) the sulphur-sulphur bond in the cystine linkage of the keratin. The hair is attacked first at the root, where it is in its immature form. After a certain time of being steeped in a solution of alkali (sodium or calcium hydroxide) and a reducing agent, normally sodium sulphide, the hair roots are dissolved, and the hair may be removed and saved.

In the processing of sheep and lambskins, the solution of alkali and sulphide is applied on the inside of the skin, allowing the solution to penetrate through the skins, attacking the wool roots, which can then be removed by 'pulling' them from the skin. This is the origin of 'slipe wool', which forms a sizeable portion of new zealand's wool production.

Step 2 - liming

The process of liming is a combination of chemical and physical action on the skin structure. The chemicals involved are similar to those in the unhairing operation. A solution of lime and sodium sulphide is used and the skins are immersed in this solution for whatever time is necessary to produce the desired effects. The process of unhairing is taken to completion during the liming process, and there is appreciable modification of the collagen due to the action of alkali.

Figure 4. Schenatic of the treatment process Figure 4. Schenatic of the treatment process |

Figure 5. Hydrolysis of amide groups

3) Swelting

In addition to the chemical action, in the presence of an alkali, swelling of the fibrous structure takes place. This is due to an osmotic pressure effect. The result is the separation of the fibres and the fibrils from one another and an opening up of the whole structure.

4) removal of unwanted material

Present in the collagen structure are globular proteins and other interfibrillary substances. These are hydrolysed and removed in the subsequent washing and bateing processes. Unwanted fats are saponified.

Step 3 - deliming and bateing

After the strong alkaline action, the skin structure is further opened up during the deliming and bateing process.

Bateing is an enzyme digestion process which continues the cleaning up process begun by the alkaline action. Bateing is carried out at ph 9-10. This is achieved by treatment with acid salts (ammonium chloride or ammonium sulphate) or carbon dioxide until the desired ph is reached.

Hydrolysis is continued by the enzyme process and further dissolution of unwanted material occurs. The main fibrous network is then cleaned up and the swelling is reduced. (see article on fellmongery for more details)

Step 4 - pickling

The main acidification process is that of pickling. The skins are agitated in a solution of salt and sulphuric acid until they are at or near equilibrium at a ph value of 3.0 - 3.5. (see article on fellmongery for more details)

The treatment process - tanning (step 5)

The tanning or stabilising process can be carried out as noted before, by means of vegetable, mineral or synthetic tanning materials. The vegetable and synthetic tanning materials are largely anionic in nature and are essentially similar in their action on skin protein.

Chemically they are complex mixtures and their chemistry is not well understood. The vegetable tans fall into two main classes.

• hydrolysable tans - complex esters of phenol and carboxylic acis and polyhydroxyphenols

• condensed tannins - mixtures of products of varying degrees of polymerisation, containing several molecules of catechin or catechin-like compounds

Syntans are largely condensation products of sulphonic acids (phenolic and naphtholic) and formaldehyde and similar general types.

Vegetable and synthetic tanning materials are widely used to modify the properties of chrome tanned leather, and as self tannages to produce sole leather, belting, football covers and other types of leather where stretch and suppleness in the leather is not required.

The main mineral tanning material is trivalent chromium sulphate. This is now widely used in the preparation of shoe upper leathers and clothing leathers, in fact, in all leathers where softness, stretch and suppleness are required. It is synthesised as follows:

Na2cr2〇7 + 3so2 + h2so4 ^ na2so4 + h2o + cr2(so4)3

the use of chromium in tanning

Chromium, a transition element which forms co-ordination complexes by using 3d orbitals to accomodate extra electrons, has an unrivalled position as a tanning agent. The complex is basic by nature and will contain hydroxyl groups associated with the chromium nuclei.

There are two main features of chromium chemistry which enable it to act as a tanning agent. Firstly, the complexes formed are of intermediate stability, and thus exchange of coordinating ligands can take place comparatively easily. Secondly, chromium has the ability to form polynuclear complexes in which cr-o-cr bridges are involved. These come about as follows:

|

Figure 6. Intermediate stability

The final process, that of oxolation, is a slow one and is not readily reversed. In a similar manner, long chains may be built up. By means of these polynuclear units the gaps between collagen chains in the skin structure can be bridged, giving the tanning action.

Individually these two properties are found in the chemistries of many other elements, and do not give any great tanning ability. But the two properties together give great tanning potency.

Chromium shows a strong tendency to form coordination compounds with molecules containing carboxyl groups. The order of stability of complex ions involving chromium with other differing ligands is:

No3_ < cl_ < so42- < h2o < so32_ < hco3_ < ch2co2- < (1) < co2_<

Co2_—(ch2)3—co2_ < (2) < co2_—co2_ < cn_ < oh_

The chromium_collagen complex lies approximately between (1) and (2) in the range of stabilities, and the order in the series has a number of practical and theoretical implications. The process of chrome tanning is now thought to involve the ligand present in the chromium complex being replaced by collagen.

The chromium-collagen compound

There are a number of ways in which the tanning action could take place, and although an ionic compound may be formed initially, it seems certain that the main chemical action is by means of coordination complexes or covalent bonds. It also seems certain that the most important coordinators are the free carboxyl groups of the collagen structure, but the amino groups and the imido groups of the peptide linkage are not excluded. This theory is implied mainly by tanning actions at various ph's. Tanning action increases as ph increases, and no tanning occurs at all when all —co2— groups of the collagen molecules are protonated.

These factors are discussed below.

The nature of the anion

Increasing ability to tan: cr(no3)3 < crcl3 < cr2(so4)3

The basicity of the chromium salt

At approximately 30-40% basicity, i.e. In the ph range 3.0 _ 3.4, the average molecular size is approximately 2-4 chromium nuclei. This appears to be the optimum for tanning. At lower basicities the molecular size is too small and the complexes cannot bridge the gap between the collagen fibres, and at higher basicities the molecular size is such that the semi- colloidal particles cannot enter into the fibrous collagen structure.

Ph value

The ph of a solution is determined by considering the difference in acidity of a solution at a given time and the equilibrium condition. Increasing ph gives greater tanning action.

Neutral salts

These also have an effect on the tanning action but this is not of great significance.

Complexing and masking agents

These are of major significance, and the type of leather produced depends very strongly on which complexing agents are present. These tend to slow down the tanning action. In some cases, e.g. That of oxalate, the ligand cannot be replaced by collagen, and hence a solution containing more than two molecules of oxalate to one of chromium will not tan. A solution of sodium oxalate will remove the chrome from chrome tanned leather. From the practical point of view the important complexing agents are sulphate, formate, acetate, phthalate, sulphite and the dicarboxylic acids. Sulphate is of low stability (hence the use of chrome sulphate powders). Formate is monodentate, is widely used, and slows the tannage down just enough to give the finished leather certain desired qualities. Acetate has an important colour effect, producing blue leather. Phthalate is bidentate (it occupies two coordination sites in the chromium nucleus).

|

|

Figure 7. The chromium nucleus

Practical aspects

How does this affect us in practice? It can be seen that in order to penetrate into the fibrous structure of the hide or skin, the chromium complex must be small. This may be obtained by a low ph and a low basicity chromium salt. When penetration has been achieved a higher ph is required; this liberates the carboxyl groups of the collagen and leaves them free for coordination, and helps in the formation of olo and oxo polynuclear chromium complexes. When some tanning has been achieved and the skin is more resistant to heat, the temperature may be raised.

Practical tanning therefore involves bringing the skin to be tanned to an acid conditon, obtaining penetration of chrome at low ph, raising the ph, and finally heating to obtain maximum fixing of chrome.

Two examples of how this goes on are as follows:

Acetate maskingthis leather is fuller, not so flat, has a higher chrome content and is green in colour. Here, because of the bidentate nature of the phthalate as a complexing agent, the chromium uptake tends to be greater and there are more links within the individual chains.

The practical measure of degree of chrome tannage is that of thermal stability. At the completion of any tannage the leather is tested to see what temperature, under wet conditions, it will stand. If it will resist 100oc (boiling water) it is considered to be satisfactorily tanned.

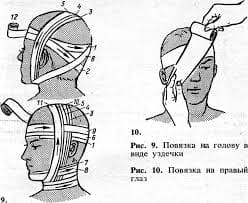

The treatment process - after tanning (steps 6 - 8) step 6 - neutralising, dyeing and fat liquoring

After tannage, leather must be neutralised to remove unwanted acids to prevent deterioration during the drying process, and to prepare the leather for the next stages in processing: dyeing and fat liquoring. Neutralising is often carried out using mild alkalis which have some effect on the chromium complex (sodium formate is a good example).

Next is dyeing, using a variety of dyestuff types. Commercial dyes are essentially mixtures of chemical compounds which can be fixed (combined) to the material to be dyed and which have appreciable resonance within the molecule giving colour. A simple example is 0range ii:

Figure 8. The using a variety of dyestuff

Its colour comes from the presence of the hydroxide group in conjunction with the azo group, allowing a high degree of resonance. It can be fixed to the material to be dyed by means of the sulphonic acid group.

In chrome tanned leathers the most reactive sites are the chromium nuclei, and these form the main points of fixation for dyestuffs. As with other processes, the main factors controlling dyeing are the physical one of locating the dye in the required position within the leather structure and the chemical one of controlling the conditions so that reasonable penetration and fixation are achieved.

A wide range of dyes are used in leather processing and some examples are: direct dyes:  |

Figure 9. Reactive, pre-metallized and acid dyes

The growing awareness of the effects on health of prolonged exposure to certain industrial chemicals has led to the prohibition of the use of certain dye stuffs - examples are direct dye- stuffs based on benzidiene. Consumer requirements for both wash and light fastness in leather goods has lead to a shift away from the more level dyeing direct and acid dyes to the faster pre-metallized and reactive dyes. Dyeing technology has had to keep up to improve the level dyeing properties of these dyes.

Fat liquoring is the process in which 'tanned' fibres are treated with reactive oils, which attach themselves to the fibrous structure, and lubricate them so that they can move readily in relation to one another, producing a soft, supple leather.

Step 7 - drying

Finally, as water is removed from the system, the chemical condition is stabilised and the final properties of the leather are determined.

Step 8 - finishing

Finishing consists of applying a surface coating - pigments or dyes bound in an organic (acrylic, butadiene or polyurethane) or protein (casein) medium. This enhances the natural qualities of the skin and covers such defects as scars, horn damage, seed scars etc., as may be present. In the case of suede leather, the suede is buffed to prepare a 'nap' and to produce a generally even texture. The main requirements for finishing are eveness and the reproducibility of colour and adequate wear and feel properties.

Levels of processing

Most sheep and lambskins are fellmongered (dewooled, limed, bated and pickled in the meatworks or independent fellmongeries). Some of these (approx 8 million per year) are further processed into chrome tanned leather (wet blue) or into finished garment leather

Within new zealand. The remainder - about 25 million - are exported in pickled condition.

About 2.5 million lambskins per year (some from imported raw skins) are tanned for wool-on lambskins used for floor rugs, babycare rugs, car seats, bedding, clothing and footwear.

These are largely exported.

0f new zealand's 2.2 million cattle hides per year, about 200 000 are exported in raw salted condition, 900 000 are chrome tanned and exported in the wet blue condition and the remainder are fully processsed into finished leather which is used in new zealand and overseas for shoe making and upholstery of cars and furniture.

Approximately 1.2 million calfskins are produced each year. These are exported in wet blue or raw salted condition.

Most of the 400 000 deerskins produced each year are converted into suede or nappa clothing leather and are exported as finished leather or as finished leather garments.

|

Figure 10. Tainnimg process

Chromium in leather industry

2.1 Environmental considerations

The leather industry is a chemical processing industry. Processing is largely carried out in a water medium and as such, there is potential for a number of environmental concerns. The regulatory framework in new zealand under the resource management act is quite strong and in essence is set up to ensure that resources are used in such a way that their use is not harmful to the environment. The framework governs discharges to air, water and on land and the responsibility is to ensure that these are not adversely affected.

The main tanneries in new zealand are sited in areas where their waste waters can be discharged into metropolitan sewerage systems and treated along with domestic sewage. However, as the metropolitan authorities are also governed by the resource management act, standards are set which must be met before discharge to the sewers can take place.

These vary from place to place depending on local conditions, but are set so that the ultimate discharge to natural receiving water reaches acceptable standards.

It can be seen from the flow chart (figure 2) that the main waste products originating from leather processing are hair or wool, salts, alkali (lime), sulphides, acids, chromium salts and dye-stuffs. Hair and wool are useful by-products, the hair being used for felt manufacture and wool for clothing and carpeting. Salt content presents no major difficulty while the acids and alkalies can be used to neutralise one another. Any excess of acid or alkali can be readily and cheaply neutralised.

The two components of normal tannery effluent which are difficult to deal with are sulphides and chromium salts. Each is undesirable for different reasons.

Sulphide

Solutions of sulphides in neutral or acidic conditions liberate significant quantities of hydrogen sulphide, which has a strong and objectionable smell (like rotten eggs) and is quite toxic _ a potential hazard for sewerage workers. The main objection to sulphide, however, is its corrosive action on the sewer fabric. Hydrogen sulphide, liberated in acidic or near-acidic conditions, dissolves in condensed moisture in the sewers above the water line. This is oxidised by various bacteria into sulphuric acid. The bacteria require water, oxygen, carbon dioxide, ammonia and a source of oxidisable sulphur to reproduce. The ph must be below 7.5. These conditions are readily obtained due to the equilibrium:

Co32- _ hco3- _ co2

(in concrete) (dissolved in (in the air) surface moisture)

The ph under these conditions will soon get down to below 7.5 and eventually, by the activities of the bacteria, concentrations of up to 5% sulphuric acid can be built up. The sulphuric acid erodes the sewer walls by forming sulphates of the calcium, aluminium and iron found in concrete. Besides being readily soluble, these salts expand as they are formed and cause crumbling of the aggregates in the concrete.

The concentration of sulphide in solution can be considerably reduced by oxidation of the sulphide to some unoxidisable form of sulphur. This can be achieved by aeration of the industrial effluent by means of air injection in the presence of manganese ions as a catalyst. Under these conditions the sulphide content can be reduced to 2-3 mg per litre, which is acceptable to drainage authorities.

Chromium

Chromium salts are undesirable for two reasons. Firstly, they can have a poisoning effect on the micro-organisms used for sewage treatment. Secondly they are precipitated as chromium hydroxide at neutral and near neutral ph's, meaning that they persist into the sludge from the sewage treatment plants. This gives a build-up of chromium (iii) hydroxide in the sludge, which is undesirable as sludge is commonly used as a fertilizer. However, chromium is an essential trace element and there is no evidence of leaching of chromium in any form from sludges uder normal conditions. As recently as 1994, the american courts prohibited the setting of limits on chromium(iii) discharges as no detrimental effects had been demonstrated.

However, in most parts of the world there are still limits imposed.

Tannery effluents are discharged in an alkaline condition. Under these circumstances any chromium present is in the form of chromium hydroxide, a light, finely divided precipitate, which is very difficult to remove. This aggregates the finely divided particles and greatly improves the rate of sedimentation so the chromium hydroxide can be removed in a normal settling operation, or by dissolved air flotation.

However, because of the limited world supply of chromium, it is necessary to develop means by which chromium tanning materials are recycled. This can be achieved in the main by saving and re-using the chromium tanning liquors. What tanning liquor is lost can be made alkaline and the chromium hydroxide separated and recovered by re-acidification.

2cr(0h)3 + 3h2s04 ^ cr2(s04)3 + 6h20

The chromium sulphate so produced is suitable as a tanning solution.

Leather production requires the use of large quantities of water. Through the use of modern equipment efforts are being made to reduce this volume. By use of the methods described above, the levels of undesirable chemicals in the water discharged from the tanneries can be reduced to levels which are acceptable to drainage authorities and if necessary acceptable for discharge into surface waters. As with all pollution control, the costs are high, and significant volumes are involved. However, the technology now exists for these problems to be controlled.

(pk = 15.4 (rai et al. 1989) or pk = 18.3 (bees and mesner 1976) [28-32].

Cr(oh)3(s) + 2h2o → cr(oh)4_ + h3o+ (4)

For more concentrated cr3+ solutions (c > 10-6 m) (rai et al. 1989), the polynuclear hydrolytic products cr2(oh)24+, cr3(oh)45+, cr4(oh)66+ could be expected (kotas and stasicka 2000).

Chromium salts

3.1 Chemistry of chromium

Chromium basic sulphate is the most widely used tanning substance today (unep 1994). The exhausted bath coming from the chromium tannage contains about 30% of the initial salt and is normally sent for cleaning up (cassano et al. 2001). Here chromium salts are entrained in the sludge creating serious problems for their disposal (gauglhofer 1986). Chromium is a micronutrient and cr salts such as chromium polynicotine, chromium chloride and chromium picolinate (crp) have been demonstrated to exhibit a significant number of health benefits in animals and humans (anderson 2000). Hazards due to environmental contamination, depend on its oxidation state (i.e. Six valence stage of chromium (cr6+) is more toxic than the cr3+ which precipitates at higher ph [27-28].

Trivalent chromium is unable to enter into cells but cr6+ enters through membrane anionic transporters. Intracellular cr6+ is metabolically reduced to cr3+. Cr6+ does not react with macromolecules such as dna, rna, proteins and lipids. However both cr3+ and the reductional intermediate cr5+ are capable of coordinated covalent interactions with macromolecules (shrivastava et al. 2002).

Chromium can exist in several chemical forms displaying oxidation numbers from 0 to vi. Trivalent and six valence forms of chromium are the most stable in the environment (shriver et al. (1994). Different chromium species also exhibit different energy levels for conversion to higher or lower oxidation states. This translitionary nature of chromium imparts certain environmental behaviour as shown earlier[29-30].

3.2 Trivalent chromium (cr3+)

Cr3+ presence, concentration and forms depend on different chemical and physical processes such as hydrolysis, complexation, redox reactions and adsorption (table 1). In the absence of complexing agents other than h2o or oh-, cr3+ exists as hexa-aquachromium (3+) and its hydrolysis products (rai et al. 1989). Cr (h2o)63+ is a moderately strong acid (pk ~ 4).

Cr (h2o)63+ + h2o → cr (oh) (h2o)52 + + h3o+ (1)

Cr (oh) (h2o)52+ + h2o → cr (oh)2 (h2o)4 + + h3o+ (2)

Cr (oh)2(h2o)4+ + h2o → cr (oh)3.aq + h3o+ (3)

The deprotonated forms are cro-h2+.aq, cr(oh)2+.aq and cr(oh).aq dominating successively within ph 4-10. Trihydroxochromium is sparingly soluble within a ph range of 5.5-12 (minimum between ph 6.5 and 11.5 (rai et al. 1989; saleh et al. 1989). Croh2+. Aq and cr(oh)3. Aq are expected to be the dominant forms of cr3 in the environment (kotas and stasicka 2000). Cr(oh)3. Aq exhibits amphoteric behaviour and at higher ph is transformed into readily soluble tetrahydroxo complex, cr(oh)4-

Table 2. Summary of various cr oxidation numbers, type and environmental behavior

| Valency | Environmental behaviour | Remarks |

| Cr | Unstable | |

| Cr1+ | Unstable | |

| Cr2+ | Readily oxidised to cr3 but stable only in the absence of any oxidant | Active under anaerobic condition |

| Cr3+ | Most stable | Considerable energy required to convert to lower or higher states |

| Cr4* | Forms unstable intermediate reactions to | Exhibits this phase during oxidation |

| Trivalent and oxidation states | And reduction | |

| Cr5* | Unstable intermediate. | Observed during oxidation and reduction |

| Cr6+ | In acidic conditions demonstrates very high positive redox potential and unstable in the presence of electron donors. | Strongly oxidizing |

Cr3+ is a hard acid which exhibits a strong tendency to form hexacoordinate octahedral complexes with a variety of ligands such as water, ammonia, urea, eth- ylenediamine, and other organic ligands containing oxygen. The complexation of cr3+ by ligands other than oh- increases its solubility when the ligands are in form of discrete molecules or ions. When, however, donor atoms are bound in a macro- molecular system, as humic acids than the cr3+ complex is more or less mobile. If the complexation from these ligands can be neglected, under redox and ph conditions normally found in natural systems, cr is removed from the solutions as cr(oh)3, or in the presence of fe3+, in the form of (crfe1-x)(oh)3 [24-28].

3.3 Chromium in the environment

25 mole fraction of cr) (sass and rai 1987). Mediation by manganese oxides was found to be the effective oxidation pathway in environmental systems (nakayama et al. 1981a; schroeder and lee 1975; bartlett and james 1979). This was due to the fact that the redox potential of the cr6+/cr3+ couple is high enough, leaving only a few oxidants capable of oxidising cr3+ to cr6+ (kotas and stasicka 2000).

2018-01-08

2018-01-08 1045

1045