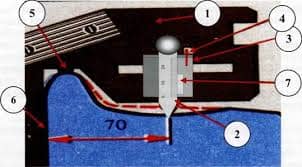

Various types are used but all do the same work. Together with the cylinder, the concaves apply a basic principle used in all models, that of passing the grain between a rapidly revolving cylinder and a stationary surface.

Spike-tooth concaves are used with spike-tooth cylinders, rasp-bar or channel-bar concaves with rasp-bar cylinders, and rubber-block concave bars with rubber-bar cylinders.

Open grates with slotted holes or perforations are placed between the concave bars. Much of the threshed grain falls through these openings to the grain pan beneath.

IV. Separating Unit. Most of your threshed grain is separated from the straw at the concaves and at the finger grate at the rear of the cylinder. But some is mixed with the mass of straw thrown from the rear of the cylinder.

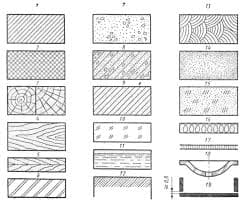

Removing this threshed grain from the mass of straw is accomplished by the straw rack (Fig. 3) which tosses and tumbles the straw and propels it to the rear. This aggressive motion separates threshed grain from the straw; the grain falls through openings in the bottom of the rack to the grain pan or to the grain conveyor. The straw travels the full length of the rack and is discharged at the rear of the combine.

A revolving beater strips the straw from the rear of the cylinder and distributes it to the straw rack. Deflectors or rotary beaters above the rack regulate the movement of the straw and deflect flying kernels.

In some models, the straw rack has four longitudinal sections. These are driven by a four-throw crankshaft which gives an alternate lifting and dropping motion as the straw is "walked" toward the rear. Figure 4 shows the flow of material from these straw "walkers' into a straw-chopping attachment which brings important advantages under certain field conditions.

2015-08-21

2015-08-21 298

298