по дисциплине « Иностранный язык»

для студентов 2 курса

заочной формы обучения

Специальность: 13.02.11

Техническая эксплуатация и обслуживание электрического

и электромеханического оборудования (по отраслям)

(базовая подготовка)

Уфа 2017

Организация-разработчик: ГАПОУ Уфимский топливно-энергетический колледж

Разработчики:

Дикушина Е.Р., преподаватель ГАПОУ Уфимский топливно-энергетический колледж

Гильмиярова Г.В., преподаватель ГАПОУ Уфимский топливно-энергетический колледж

Обсуждена на заседании МЦК «Иностранный язык»,

Протокол № _ от «_» __________ 201_года

Контрольная работа №2

Лексическая часть

Тема №1 Моя будущая профессия

1. Пройдите по ссылке.

2. Ознакомьтесь с предложенным материалом.

3. Составьте план текста.

Http://pullion.com/book-reports/126-essay-my-future-profession.html

Тема № 2 Образование

1. Прочитайте текст со словарем.

2.Выполните упражнение после текста.

THE BIRMINGHAM UNIVERSITY

The University of Birmingham was founded in 1900. At present it has more than 20,000 students. An emphasis upon research in all schools is one of the characteristics of the University.

Manufacturing and Mechanical Engineering is one of five Schools of Engineering at the University of Birmingham. Its other Schools are Chemical Engineering, Civil Engineering, Electronic and Electrical Engineering and Metallurgy and Materials.

The courses given in the School are designed primarily to provide a broad education in the fundamental mechanical engineering sciences and in economics and business studies. The advanced courses in the School of Manufacturing and Mechanical Engineering lead to careers in the fields of design, research, development and production in industry; the government service; the national research laboratories and higher learning institutions; and to those in some branches of teaching.

One group of courses serves the Industrial Engineering stream and the other serves the Engineering Science stream. The former is intended for students whose interests lie mainly in the design and production side of engineering, the latter is meant for those who are analytically-minded and who wish to study in depth the theoretical techniques used by engineers. After following a common first year and before entering the second year, students are divided into two streams on the basis of their own choice. The courses of study include mechanical production, electronic and electrical engineering, metallurgy, mathematics and economics. They are supported by laboratory and drawing office exercises. In both cases students are engaged in practical work with engineering firms during the summer vacation.

Завершите предложения, выбрав соответствующие окончания

1. The School of Manufacturing and Mechanical Engineering is...

2. The courses given include...

3. After the first year...

4. They are...

5. Both streams are served...

6. The Engineering Science stream course is intended for students...

7. Students who are interested in design and production...

8. The courses of study are supported by...

9. During summer vacations students are engaged in...

a) by different groups of courses.

b) the Industrial Engineering stream and the Engineering Science stream.

c) practical work with engineering firms.

d) one of the five Schools of Engineering at the University.

e) laboratory and drawing office exercises.

f) students are divided into two streams.

g) study the Industrial Engineering stream course.

h) mechanical engineering sciences, economics and business studies.

i) who wish to study the theoretical techniques.

Тема № 3 Профессия инженера

1. Пройдите по ссылке.

2. Ознакомьтесь с предложенным материалом.

3. Составьте план текста.

http://education.seattlepi.com/classes-must-taken-order-become-engineer-2705.html

Тема № 4 Ученые и их изобретения

1. Прочитайте текст со словарем.

2.Выполните упражнение после текста.

JAMES WATT

James Watt was born in Greenock, Scotland, and was taught at home. Later he went to Greenock Grammar School.

His technical expertise seems to have been obtained from working in his father’s workshop and from early in life he showed academic promise. His early formal training was as an instrument maker in London and Glasgow.

Watt combined the expertise of a scientist with that of a practical engineer, for later he was not only to improve the heat engine but also to devise new mechanisms.

Watt was interested in making experimental models of steam engines and this marks a historical milestone in engineering development, for they were the first experimental apparatus purposely constructed for engineering research. Watt’s early interest in steam arose from experience in repairing a model steam engine in 1764, and in 1765 he invented the separate steam condenser. In 1769 he took out a patent on the condenser in which steam came into direct contact with cold water. That was a milestone by which steam engineering reached its practical and usable form.

In 1784 he took out a patent for a reaction turbine at a time when continental engineers were only considering similar approaches. An improved centrifugal governor was to follow in 1788 and a design for a pressure gauge in 1790.

In the development of the steam engine James Watt represents the perfecting of a sequence of stages beginning with the Newcomen engine and ending with the parallel motion and sun/planet gearing.

The latter is said to have been invented by William Murdock but patented by Watt.

In the scientific field Watt’s finest memorial, apart from steam engines, is his establishment of the unit of power — the rate of doing work. He coined the term horsepower (hp), one horse being defined as equivalent to 33,000 ft lb/min.

James Watt died in 1819 in Heathfield, after a life of incomparable technical value. Later, a statue to Watt was placed in Westminster Abbey.

На основании полученной из текста информации заполните следующую таблицу.

| Time | Watt’s activity and its results |

| repairing a model steam engine | |

Тема № 5 Единицы измерения

1. Пройдите по ссылке.

2. Ознакомьтесь с предложенным материалом.

3. Составьте краткую аннотацию текста.

http://www.europeword.com/blog/europe/the-metric-system-in-europe/

Тема № 6 Металлы

1. Прочитайте тексты со словарем.

2. Составьте глоссарий основных слов и понятий по теме.

1.FERROUS METALS

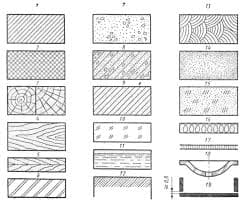

Different metals are widely used in the machine-building industry. There are two groups of metals: ferrous metals and non-ferrous metals.

Ferrous metals consist of iron combined with carbon, silicon, phosphorus and other elements. Carbon is the most important of all elements present in ferrous alloys. Ferrous metals are used in industry in two general forms; steel and cast iron, which differ in the quantity of carbon content". These two ferrous alloys are derived from pig iron which is produced in a blast furnace in the form of pigs. Metals are usually melted and poured into a form which is called a "mould". This process is known as casting. The cast metal is shaped in the mould where it cools and solidifies. The shop where metals are cast is called a "foundry". Castings are used in building engines, automobiles and airplanes, and different types of machinery. Steel is iron with a very little carbon content (from 0.05 to 1.7 per cent), which makes it much stronger than iron and is therefore widely used in machine-building. But very much carbon makes steel brittle, which reduces its strength. Therefore the carbon content in steel is confined to certain limits. Cast iron contains a higher percentage of carbon than steel does (more than 2.0 per cent). It is very cheap, in fact, it is the cheapest of all the engineering metals used in machine-building.

NON-FERROUS METALS

Non-ferrous metals are more expensive than ferrous metals and are used only when some characteristic not possessed by iron of steer is essential or desirable in application. These characteristics are: high electrical "and thermal conductivity, high corrosion resistance, non-magnetic qualities, light weight, etc.

The metals most frequently used to make non-ferrous metal castings are copper, tin, zinc, lead, nickel, gold and aluminium.

Copper is a reddish-brown, tough metal. It has very high electric conductivity and high corrosion-resistant qualities. Copper is used for making electrical contacts and wires, pipes, telephone cables, tanks, water heaters, etc.

Zinc is a hard, brittle, bluish-white metal that is employed in the pure form as sheet zinc.

Lead is a very heavy bluish-grey metal/which is very soft. This metal is highly resistant to corrosion, but its strength is so low that it must be supported by a core of some other metal. Lead is used for lining pipes, acid tanks and coating electrical cables.

Aluminium is a soft, silvery white metal. It is light in weight, has high corrosion-resistant qualities and is used for automobile and airplane parts as well as for making different light-weight objects used in everyday life such as: frames, cooking utensils, chairs, etc.

Tin is a silvery, corrosion-resistant metal. Tin is hardly used in pure form, but is employed as an alloying element.

Nickel is a hard, tough, silvery metal. It has high corrosion-resistant qualities and is used for plating other metals such as iron or brass.

There are many applications of non-ferrous metals in the unalloyed state, but in most cases, some alloying element is added. The above-mentioned non-ferrous metals may be mixed in various proportions to form many alloys, chief among them being brasses, bronzes, and aluminium alloys.

Brasses are yellowish or reddish alloys of copper and zinc in different proportions (about 60 per cent copper and 40 per cent zinc, but some brasses contain as high as 90 реr cent copper with only 10 per cent zinc). An addition, of tin makes brasses stronger. Brasses are very ductile and may be treated without heating them. They are corrosion-resistant and are used for making musical instruments, bearings.

Bronze is an alloy containing primarily copper and tin, but other elements may be added to the alloy to increase ' its properties such as hardness and resistance to wear. The most common bronzes are known as straight bronze, phosphor bronze, and manganese bronze.

Aluminium Alloys. Aluminium is used extensively for castings that are; to be light in weight, light in colour, or that must not rust. Since aluminium is too soft for making castings, it is necessary to mix some other metals with it. The metals that alloy freely with aluminium are copper, zinc, and iron.

2018-01-08

2018-01-08 1010

1010