A key step in finite element analysis procedure is to mesh the model. Meshing is process of breaking the model into small pieces (finite elements). The network of nodes and elements is called a mesh.

A key step in finite element analysis procedure is to mesh the model. Meshing is process of breaking the model into small pieces (finite elements). The network of nodes and elements is called a mesh.

There are two broad types of mesh-generation methods: structured and unstructured meshes.

A structured mesh B is formed by grid-based subdividing of the geometry.

Unstructured mesh are formed automatically. The size of neighboring elements can be significantly different for unstructured mesh. There are no "rows and columns" for such mesh, A. There are more nodes than elements for unstructured mesh with a large number of elements. The ratio between elements and nodes is approximately 2:1 for 2D unstructured mesh and 6:1 for 3D unstructured mesh with tetrahedral elements.

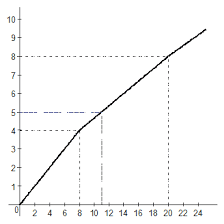

Smaller mesh size h corresponds to a larger number of finite elements in the model. The calculation time increases exponentially as size decreases. The errors decrease for finer mesh but never fall to zero since FEM is always an numerical approximation.

Smaller mesh size h corresponds to a larger number of finite elements in the model. The calculation time increases exponentially as size decreases. The errors decrease for finer mesh but never fall to zero since FEM is always an numerical approximation.

A linear element requires a finer mesh than a parabolic (quadratic) or a cubic element.

A linear element requires a finer mesh than a parabolic (quadratic) or a cubic element.

Structured mesh B is preferable over an unstructured mesh, A.

Rectangular 4 node elements, C are more preferable than triangular elements, B.

Quadratic (second order) triangular elements, D have at least the same accuracy as first order 4 node elements, C.

Rectangular 8 node elements, E are preferable over triangular second order elements, D despite their larger size.

Cubic displacement approximation F does not need fine meshing.

The FEM is an approximate method. The accuracy of the predictions depends on the assumptions made within the element types and the mesh. A fine mesh is required where there are stress and strain gradients (rates of change). A coarse mesh can be used in areas of reasonably constant stress or regions that are not of user's interest. Users must be able to identify regions of stress concentration. Points of interest may consist of fracture points of previously tested structure, holes, fillets, corners, contact zones, complex details, and high stress areas.

The FEM is an approximate method. The accuracy of the predictions depends on the assumptions made within the element types and the mesh. A fine mesh is required where there are stress and strain gradients (rates of change). A coarse mesh can be used in areas of reasonably constant stress or regions that are not of user's interest. Users must be able to identify regions of stress concentration. Points of interest may consist of fracture points of previously tested structure, holes, fillets, corners, contact zones, complex details, and high stress areas.

The accuracy decreases if the sizes of the neighboring elements near stress concentrators are significantly different.

The accuracy decreases if the sizes of the neighboring elements near stress concentrators are significantly different.

The shape of finite elements affects the accuracy. It is preferable not to have sharp corners in finite elements. Elements with similar sides produce smaller errors.

The shape of finite elements affects the accuracy. It is preferable not to have sharp corners in finite elements. Elements with similar sides produce smaller errors.

The FE mesh is built without gaps between elements. Both triangular and rectangular elements can be used in the same FE model.

The FE mesh is built without gaps between elements. Both triangular and rectangular elements can be used in the same FE model.

The nodes are numbered sequentially for manual meshing. It is forbidden to build four node elements with an obtuse (> 180o) inner corner.

The nodes are numbered sequentially for manual meshing. It is forbidden to build four node elements with an obtuse (> 180o) inner corner.

2015-08-13

2015-08-13 412

412