Exercise 1. Answer the following questions.

1. What is the diesel engine? 2. What cycles does the diesel engine have? 3. What is stroke? 4. What does the four-stroke cycle consist? 5. How is the four-stroke cycle completed? 6. What is going on at the top dead centre? 7. What is going on at the bottom dead centre? 8. How is the two-stroke cycle completed? 9. What is used instead of valves? 10. How does the two-stroke cycle work?

| maintenance | содержание и техническое обслуживание, техническая эксплуатация, уход, (текущий) ремонт | |

| dipstick | футшток | |

| to stand still | находиться не в рабочей состоянии | |

| draining | слив | |

| to unscrew | отвинчивать | |

| to screw | завинчивать | |

| drain plug | сливная пробка | |

| bottom | дно, днище | |

| crankcase | картер двигателя | |

| to fill; to refill | наполнять; наполнять вновь | |

| refilling | повторное наполнение | |

| to wipe | протирать | |

| rag | ветошь | |

| fluff | пух, пушок, ворс | |

| cotton waste | зд. хлопчатобумажная ветошь | |

| to dip | погружать, окунать | |

| lube oil suction strainer | фильтр масла на входе | |

| sump | отстойник, сборник, сточная цистерна | |

| crack | трещина | |

| upper | верхний | |

| piston ring | поршневое кольцо | |

| condition | состояние | |

| deposits | отложения | |

| carbon | нагар | |

| excessive | излишний | |

| externally | с наружной стороны | |

| scale | накипь | |

| wear | износ | |

| to renew | заменять | |

| top | верхняя часть | |

| to adjust | регулировать | |

| clearance | зазор | |

| joint | соединение | |

| lever | рычаг | |

| alignment | регулировка, выравнивающая, центровка, настройка, просветка (линий вала) | |

| bearing | подшипник | |

| readings | показания, данные, замеры |

Exercise 2. Read and translate the text

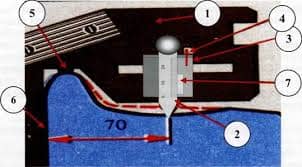

Check the lube oil pressure daily. The pressure should be 1,5 Kg per sq.cm = 21 Ibs/sq. in (psi). Keep the oil level up to the full mark of the dipstick. Make control when the engine stands still. The lube oil should be changed the first time after 50 working hours, the next time after another 150 working hours and then at least once a year. Draining is made by unscrewing the drain plug at the bottom of the crankcase just after stopping the engine when the oil is warm and easy to drain. Before refilling with fresh oil wipe out the inside of the crankcase with a clean rag (use material free from fluff, do not use cotton waste). Dip the rag in gas oil and clean the lube oil suction strainer placed on the drain plug and clean the sump. When changing the lube oil, clean the lubricating oil filter with petrol or gas oil. Refill the sump with fresh lube oil.

Pistons should be examined frequently for cracks. The upper piston rings should be examined once a month during the first six months service and than as necessary depending on their condition. At intervals of six months piston heads if cooled mast be examined for deposits of carbon in cooling spaces -and cooling pipes. Exhaust valves, manifold and cylinder ports should also be examined and excessive carbon deposits should be removed. Cylinder liners must be examined externally for deposits of scale. The liners should also be examined for wear and renewed if necessary. The clearance of the connecting rod - top and bottom ends should also be examined and adjusted if necessary. At intervals of one year the manoeuvring gear should be examined for wear at the joints of levers and rods. The alignment of the crankshaft should be checked and corrected if necessary. The main bearings, should be examined and readings taken for wear.

Exercise 3. Answer the questions.

1) How often should the lube oil pressure be checked?

2) What should be the pressure? When should the lube oil be changed the first time?

4) How is draining made? When is the oil easiest to drain?

5) Where is the drain plug positioned?

7) When is it necessary to wipe out the inside of the crankcase?

8) What should the pistons be examined for?

9) Where is usually carbon deposited? What should be done with carbon deposits?

10) How often should the maneuvering gear be examined?

Exercise 4. Give the Russian equivalents of the following.

lube oil pressure, drain plug, inside of the crankcase, lube oil suction strainer, deposits of scale

Exercise 5. Translate into Russian

Explosion in crankcase. The usual cause is presence of mixture of oil and air at concentration higher then nominal. In addition there must be a source of high temperature, sufficient to start combustion. It is called a hot spot. The explosion causes a flame and pressure wave. To prevent explosion you should minimize oil and air mixture and be careful during ventilation of crankcase. On some ME special crankcase relief valves are installed.

Exercise 6. Made up a dialogue of your own based on the one given below.

2015-08-21

2015-08-21 471

471