| Fabric plies | ||||

| Б 800 | БКНЛ | ТА-150 | ТК-20 | |

| Nominal strength in N per mm of width | ||||

| Maximum allowable load p0 to a ply in N per mm of width | ||||

| Design thickness δ0 of fabric plies with rubber interlayers, mm | 1.5 | 1.2 | 1.2 | 1.3 |

| Number of plies if belt width b, mm 20-71 80-112 125-560 | 3-5 3-6 3-6 | 3-5 3-6 3-6 | -- -- 3-4 | -- -- 3-4 |

Check the requirement

d=d0× z £ 0.025× d 1;

1.5∙3£0.025×224; 4.5£5.6mm. Condition is satisfied.

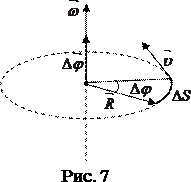

7.10. Determine contact angle factor C α

.

.

7.11. Determine factor Cv, with taks into account the effect of the belt speed

Cv = 1.04 – 0.0004 × V 2=1.04 – 0.0004 ×17.0562=0,9236.

7.12. Determine service factor Cs:

- Cs = 1 for steady operation (belt conveyers, lathes and grinding machines);

- Cs =0.9 in the case of moderate vibration (chain conveyers and milling machines);

- Cs =0.8 in the case of considerable vibration (flight conveyers, planing machines).

The value of Cs is to be reduced by 0.1 in two-shift operation and by 0.2 in three-shift operation.

Let us assume that we have moderate vibration. That is why Cs =0.9.

7.13. Determine factor C Θ, that takes into account the belt position in the space.

- C Θ = 1 for horizontal drives and inclined at up to 60°;

- C Θ = 0.9 for drives inclined at over 60° to 80°;

- C Θ = 0.8 for drives inclined at over 80° to 90°.

In our case we assume C Θ = 1.

7.14. Determine the allowable load to 1mm of ply width, N/mm

[ p ]= p 0 × C a × CV × Cs × C Q=3∙0.966∙0.9236∙0.9∙1=2.409 N/mm.

7.15. Find the belt width

and round off obtained magnitude according to series of standard values: 20; 25; 32; 40; 50; 63; 71; 80; 90; 100; 112; 125; 140; 160; 180; 200 and so on. Assume b =50 mm.

7.16. Determine the pulley width B according to table 7.2.

2015-08-21

2015-08-21 295

295