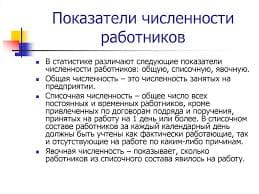

Allowable mean pressure [p], in MPa

| n1, rpm | Chain pitch, mm | |||||||

| 12.7 | 15.875 | 19.05 | 25.4 | 31.75 | 38.1 | 44.45 | 50.8 | |

| - | - | |||||||

| - | - | - | ||||||

| - | - | - | - |

8.6. Determine the chain pitch

,

,

where T1 is in N×m.

Round off the pitch to the nearest standard value according to the table 8.1. In our case assume t = 31.75 mm.

8.7. Specify the allowable mean pressure according to table 8.1 by interpolation [p]. On multiplying it by

Kp = 1 + 0.01·(z1-17) = 1 + 0.01·(26-17)=1.09 we get finite magnitude of [p] = 29·1.09=31.61MPa

8.8. Determine the effective mean pressure.

For that we

- find chain speed

;

;

- find turning (tangential) force

;

;

- look up the projected hinge area Sh using table 8.2. In our case Sh=262 mm2

Then the effective mean pressure

.

.

If this inequality is not right it is necessary to increase the pitch t.

;

;

inequality is right.

8.9. Determine the number of links in the chain

,

,

where  is the chain length in pitches;

is the chain length in pitches;  ; a» (30…50)·t; zS = z1 + z2;

; a» (30…50)·t; zS = z1 + z2;  . Round off obtained magnitude to even integer numeral.

. Round off obtained magnitude to even integer numeral.

In our case: at = 45; zS = 26 + 65 = 91;  ;

;

8.10. Specify the centre distance

The slack side of the chain should have a slight sag f» 0.01·a, for which purpose the design centre distance is reduced by 0.2 to 0.4 %.

|

|

|

Assume that a = 1418.76 mm.

8.11. Determine the pitch diameters

- of the driving sprocket  ;

;

- of the driven sprocket  .

.

8.12. Determine the addendum diameters

where d1 is the roller diameter (table 8.2).

8.13. Determine the dedendum diameter

,

,

.

.

2015-08-21

2015-08-21 474

474