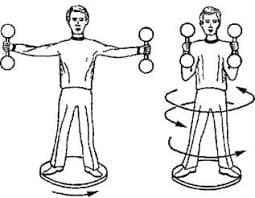

Protective grounding is dedicated electric connecting to the ground of metallic parts, which may turn out to be under voltage. Its purpose is to eliminate the risk of electric injury when power has short circuit to the facility’s case. Principle of its operation is reducing breakaway and pace voltage caused by short circuit to safe limits. It’s achieved by equaling potentials of grounded facility and ground (fig. 3.14).

a

b

Fig. 3.14 Protective grounding: a – external grounding scheme (1 - grounding electrodes; 2 - ground wire; 3 – grounded facilities); b – scheme of person’s connection to facility’s case when phase has short circuit to the case

Protective grounding is applied in three-phase power lines with voltage up to 1000 V with neutral of any mode of operation.

Constructively protective grounding is the assembly of ground wire and grounding electrodes.

Ground wire is conductor to connect grounded facility with grounding electrodes.

Grounding electrodes is the assembly of conductors contacting ground or its equivalent. They may be either special vertical and horizontal electrodes or another metallic things put under ground.

Vertical electrodes are made from steel pipe of 3 - 5 cm in diameter and steel corner plate having section size from 40´40 to 60´60 mm and length 2.5 - 3 m. It’s possible also to use metallic wires of 10 - 12 mm in diameter. Horizontal electrode (flat bar) is used to get all the electrodes together in whole assembly, it can be made from steel strip with section size 4´12 mm or steel pipe with diameter of 6 mm as minimum.

Grounding electrodes are deepen into the ground so that the upper flat bar should be at 0.7 - 0.8 m under earth. First they dig a trench to the needed depth and then drive electrodes into the earth.

As “natural” grounding electrodes the following can be used:

- water supply pipelines, and another ones except those with inflammable substances or explosive gases or pipelines covered with corrosion-resisting insulation;

- casing of artesian well, bore-hole, bore pit;

- steel armature, ferro-concrete reinforcement, which has contact with the ground;

- lead cover of cable installed in the ground.

Natural grounding usually has a low ground resistance what makes it cheap and practicable. However its use has some demerit as it’s reachable for not electrician personality what remains risk to have it damaged and disconnected from all grounding system.

In accordance to the Rules for Installing Power Facilities (RIPF) resistance of grounding should not exceed:

- 4 ohm – in power facilities under voltage up to 1000 V; using generator or transformer with power up to 100 kilowatt, grounding resistance is allowed to be up to 10 ohm;

- 0.5 ohm – in power facilities under voltage over 1000 V with effective grounded neutral;

-  , 10 ohm as maximum – in power facilities under voltage over 1000 V with insulated neutral; if grounding is simultaneously used for in power facilities under voltage up to 1000 V, grounding resistance should not exceed

, 10 ohm as maximum – in power facilities under voltage over 1000 V with insulated neutral; if grounding is simultaneously used for in power facilities under voltage up to 1000 V, grounding resistance should not exceed  , 10 ohm as maximum (or 4 ohm, if needed for power facilities under voltage up to 1000 V). Ig – current in the ground.

, 10 ohm as maximum (or 4 ohm, if needed for power facilities under voltage up to 1000 V). Ig – current in the ground.

Protective grounding is to be applied to metallic parts of facility, which may turn out to be under voltage caused by insulation damage. It’s obligate to use in extreme danger areas and for outside installations under voltage over 42 V of AC and over 110 V of DC, in areas without high danger – under voltage over 380 V of AC; over 440 V of DC. Only in explosion risk areas grounding is applied irrespective to the voltage.

Protective grounding is not applied to case of facility, instrument or tool if they are installed at the grounded metallic construction, switchboard, distribution cabinet or tool frame of machine and mechanism and have reliable electric connection with grounded base, and also insulation armature of all types, extract ventilation, cantilever and lighting armature when they are installed at wooden beam of aerial power line, or wooden construction of outer substation.

Protective neutralizing is dedicated connecting metallic parts, which may turn out to be under voltage to the neutral wire (fig. 3.15). It’s the basic way for electric injury prevention in case of touching case of facility that turned out to be under voltage caused by insulation damage or one-phase short circuit in facilities under voltage up to 1000 V of the power line with grounded neutral. Protective neutralizing has the same purpose as protective grounding: to eliminate risk of electric injury in case of phase short circuit to the power facility’s case.

Fig. 3.15 Protective neutralizing: 1 - case; 2 – short circuit preventive elements (pull-out fuse, fuse plug); Ro – resistance of neutral grounding; Rr – resistance of reserve neutral grounding; Isc – short circuit current.

It’s achieved by automatic shutting down of damaged facility. It works protective when case or cover of electric facility, people may touch during operation, gets under voltage due to insulation damage. This voltage is transferred into one-phase short circuit, which is capable to shutdown power when quite high current passing through fuse plug disconnects the power line.

For fast shutting down the following condition should be fulfilled:

Isc³kInom, (3.26)

where Isc - short circuit current, A; Inom – fuse nominal current, A; k - short circuit current ratio.

It’s important to notice that protective neutralizing never ensures complete safety as people may be still at the risk of electric injury until protective fuse reacts to short circuit. Protective neutralizing is used in three-phase power line under voltage 1000 V as maximum with grounded neutral.

Protective shutdown is the fast measure to automatically disconnect power facility as a danger of electric injury appears. Risk of electric injury can arise in case of grounding failure, what may be caused by insulation damage and reduction of conductors’ insulation resistance to the ground, in case of overly high voltage in the power line caused by short circuit between high-voltage and low-voltage windings of transformer. In these cases electric parameters of the power line get changed, what in turn can be used to activate protective shutdown. Protective shutdown should comply with the following requirements: high sensitivity (capability to react to small changes of the incoming signal), short turn-on time (under 0.2 s), selective work (capability to shutdown power only of damaged facility), inside control (capability to shutdown power when protective shutdown is out of order), reliability.

Protective shutdown is recommended to use as basic or additional protection if it can’t be reached by installing protective grounding or if it’s cheaper.

It’s used in power facilities under voltage 1000 V as maximum, mobile facilities with insulated neutral, when installing of protective grounding is inconvenient; using electric tools in stationary facilities; in conditions of high electric danger or high explosion risk.

2015-08-21

2015-08-21 421

421