During the middle and late 20th century, rotary drilling has become the preferred method for penetrating underground formations. In this method, a special tool – the drill bit – rotates while bearing down on the bottom of the well, thus gouging and chipping its way downward. Probably the greatest advantage of rotary drilling over cable tooling is that the well bore is kept full of liquid during drilling. A weighted fluid (called drilling mud) in the bore hole serves two important purposes: by its hydrostatic pressure, it prevents the entry of formation fluids into the well, thus preventing «blowouts» and «gushers». In addition, the drilling mud carries the crushed rock to the surface, so that the drilling is continuous until the bit wears out.

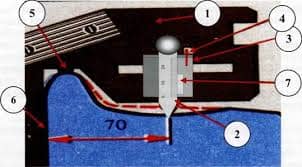

The drill bit is connected to the surface equipment through a drill pipe, a heavy-walled tubing through which the drilling mud is fed to the bottom of the bore hole. In most cases, the drill pipe also transmits the rotary motion from a turntable at the surface to the bit at the bottom of the hole. The top piece of the drill pipe is a tube of square or octagonal cross section called the kelly, which passes through a square or octagonal hole in the turntable. At the bottom end of the drill pipe are extra-heavy sections called drill collars that serve to concentrate the weight on the rotating bit. The drilling mud leaves the drill pipe in such a way that it washes the loose rock from the bottom and carries it to the surface. Drilling mud is carefully formulated to assure correct weight and viscosity characteristics for its required tasks. After screening to remove the rock chips, the returning mud is held in open pits to be recirculated through the well. The mud is picked up by piston pumps and forced through a swivel joint into the top of the drill pipe.

The characteristic tall derrick contains the hoisting equipment that is used to raise and lower the drill pipe into the well. The drill bit wears quickly and requires frequent replacement, making it necessary to pull the entire drill string from the well and stack it at one side of the derrick. Joints of drill pipe are usually nine metres (30 feet) long. Sections of two or three such joints are separated and stacked vertically while the bit is being changed. Drilling mud is left in the bore hole during this time to prevent excessive flow of fluids into the well.

Such rotary drilling techniques as those described have made it possible for wells to be drilled to depths of more than 7,600 metres (25,000 feet). Wells have been drilled in both coastal waters and in the open sea. In relatively shallow waters (less than 60 metres [200 feet]), the wells are usually drilled from platforms that rest on the bottom; the drilling platform is constructed above the highest expected waves. In deeper waters and for exploratory work, drilling is done from a floating vessel that is kept in place by a combination of anchors and motors. Since the fixed platforms are quite expensive, many (20 or more) wells are often drilled from the same platform. Yet for most efficient coverage, the wells must enter the producing formation with more than 300 metres (1,000 feet) between them. Thus, each well except one has to be drilled in a precise slantwise direction. This directional drilling is achieved with a tool called a whipstock, which causes the drill bit to veer slightly in the desired direction. The whip-stock is used at intervals until the total desired angular deviation is reached. Sharp bends in the bore hole must be avoided because the rather rigid drill pipe has to bend through the deviation while rotating.

One variation in rotary drilling has involved introducing a fluid-powered turbine at the bottom of the bore hole to produce the rotary motion of the bit. The turbodrill is about nine metres long and is made up of four basic parts: the upper bearing, the turbine, the lower bearing, and the drill bit. The upper bearing is attached to a drill pipe, which does not rotate or rotates at a much slower rate than the drill bit (six to eight revolutions per minute), but it is used to regulate the weight of the drill bit and to carry the drilling mud that powers the turbine. The drill bit rotates at a much faster rate (500 to 1,000 revolutions per minute) than conventional rotary drilling. The power source for turbodrilling is the mud pump, which pumps drilling mud through the drill pipe and upper bearing and into the turbine. The mud is diverted onto the rotors of the turbine, turning the lower bearing and the drill bit. As in conventional rotary drilling, the mud passes through a hollow portion of the lower bearing to cool the drill bit. Although turbodrills are in widespread use in the U.S.S.R., they are comparatively rare in the United States, where the rotary tool drilling method has remained predominant for most applications.

2015-10-13

2015-10-13 1016

1016