Peat surface mining methods and equipment selection

MikhailovAleksandr

National Mineral Resources University, Saint Petersburg, Russia

Abstract

Peat plays an important role in the energy systems of the Nordic countries. The largest reserves of peat are in Canada and Russia. It has been a domestic fuel with a long tradition of use especially as a fuel in times of crisis. According to research conducted in Russia, peat is a very suitable raw material for local fuel production. The ash content of the peat local fuel is smaller than in cool, and the quality of the fuel is high.

The purpose of this paper is to develop performance criteria for fleet selection in surface mining of natural peat as a raw material for factory-made local fuel.

Proper fleet selection, in a way that it secures the production needs of a mine as well as minimizes costs of production, is one of the real challenges of mine planners. Classifying the equipment selection process into three phase’s: type of fleet, size of equipment and calculation of required numbers, the present article focuses on different application methods in each of these phases, their advantages and shortcomings.

Equipment selection involves choosing the optimum hydraulic excavator – truck combination to operate the peat raw material handling process. There are for primary considerations: maximum productivity; minimum power intensity of the process; purchasing and operating costs as low as possible; compatibility. Not all trucks and hydraulic excavators can work properly on the wet peat deposit surface.

Keywords

surface mining, open pit mining, peat excavation, loading, hydraulic excavators, tractors and semitrailers

Introduction

Surface peat mining is the most common method of peat production in the world. Current interest in peat as a fuel source can be linked directly to increases in the prices of conventional fuels, such as oil and natural gas. The purpose of this paper is to develop performance criteria for fleet selection in new surface mining of natural peat as a raw material for factory-made local fuel.

In recent years, a hydraulic excavator and tractor-semitrailer combination has been used in surface mining due to technological developments. Choosing appropriate equipment is one of the most important factors for production system efficiency.

Equipment selection involves choosing the optimum hydraulic excavator – truck combination to operate the peat raw material handling process. There are for primary considerations: maximum productivity; minimum power intensity of the process; purchasing and operating costs as low as possible; compatibility. Not all trucks and hydraulic excavators can work properly on the wet peat deposit surface.

Peat Surface Mining Method

The peat mining method selection problem focuses on choosing the correct excavation method for the

given peat deposit conditions. Renewal of peat fuel production at new technical and technological levels, will allow to provide necessary reliability of fuel maintenance.

Extraction of peat raw materials is based on excavation from peat deposit, drying and stockpiling. The focus was on following aspects[1]:

- Minimizing the environmental impacts;

- Maximizing the utilization of solar and wind energy and minimizing the weather sensitivity;

- Current cost level;

- Improving the final product quality.

For the majority of all technological processes involved with peat production the process of peat drying is the primary and most important process. Renewable energy sources for the peat drying process based on physical phenomena in nature include wind and solar energy.

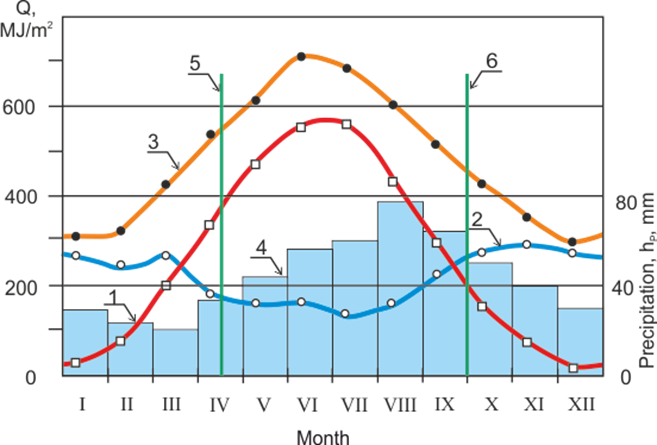

Analysis of the potential of natural renewable energy sources, which can be utilized during peat production, was based on examination of climatic history (conditions) of the Northwest region of Russia [2]. The interactions of three primary climatic effects are considered: solar radiation, precipitation and wind (fig.1).

Fig.1: Monthly average energy balance on a peat field in Northwest of Russia:

1 - solar energy; 2 - wind energy; 3 - total of solar and wind energy; 4 - monthly precipitation; 5 - beginning of peat excavation season; 6 - ending of peat excavation season

In summary, solar radiation is at its maximum during the months of March through September. Precipitation (rain) is at a maximum in summer and autumn, with precipitation in the winter months predominantly as snow. Wind energy (speed) is usually moderate (medial monthly wind speed of 4-5 m/s), with maximum speeds occurring usually months with low solar radiation (September - May).

Normally the production season in Russia is from May 18 through August 31. The extraction of peat can be applied from April until September.

The quantity of energy above the surface of the peat fields can be estimated as the total of solar and wind energy (fig. 1). The analysis of the energy balance for the region demonstrates that energy balance of solar and wind energy are ‘measured’ values, lines 1 and 2 (total energy – line 3).

It is generally accepted that the degree of utilization of solar energy for milling peat production is 15-20 % [2]. The consensus is that wind essentially does not influence peat drying, and is not typically used in general peat production methods for drying. Its role is reduced to venting of the processed peat, i.e. ablation and replacing the moisture saturated air with dry air. The average wind speed along the ground stratum of a peat field is 0.2-0.5 m/s. Thus, the peat drying process uses no more than 1 % of wind energy.

At the modern level of technical development of civilization, currently the following can potentially be realized. Up to 1/5 the potential solar energy and up to 1/3 the potential of wind energy can be utilized. Consequently, in our case the energy use limit for peat production is 1/4 of the total annual energy potential.

Analyzing the technological level of peat production manufacturing processes, we selected two key directions to enhance the degree of energy potential use:

- magnification of peat production season duration;

- intensifying the processes of peat excavation and drying.

Due to the climatic conditions in Northwestern Russia, the optimum moisture content for peat processing is peat with a moisture content range of 60 – 65 %. Using the “wet harvesting” method, peat deposit maintain their wetland function and can regenerate to become a carbon sink within 2-3 years. The main fleet for excavation of peat raw materials consists from excavator, tractors and semitrailers (fig.2).

Fig.2: Peat mining process:

1 -excavation and loading of peat;2 - local transportation on field; 3 - leveling, disking, drying and harvesting; 4 - stockpiling; 5 - loading with crushing and separation; 6 - transportation on plant.

Advantages of a thispeat production method:

- reduction of influences by environment;

- expansion of a production season;

- optimum use of weather conditions;

- economic efficiency of production in 20 times is higher, than the current methods;

- the quantity of peat resources suitable for use increases;

- fast restoration of the peat areas absorbing CO2.

2018-01-21

2018-01-21 593

593