Materials science and Technology is the study of materials and how they can be fabricated to meet the needs of modern technology. Using the laboratory techniques and knowledge of physics, chemistry, and metallurgy, scientists are finding new ways of using metals, plastics and other materials.

Engineers must know how materials respond to external forces, such as tension, compression, torsion, bending, and shear. All materials respond to these forces by elastic deformation. That is, the materials return their original size and form when the external force disappears. The materials may also have permanent deformation or they may fracture. The results of external forces are creep and fatigue.

Compression is a pressure causing a decrease in volume. When a material is subjected to a bending, shearing, or torsion (twisting) force, both tensile and compressive forces are simultaneously at work. When a metal bar is bent, one side of it is stretched and subjected to a tensional force, and the other side is compressed.

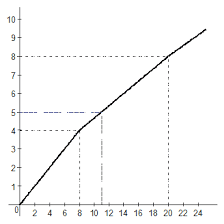

Tension is a pulling force; for example, the force in a cable holding weight. Under tension, a material usually stretches, returning to its original length if the force does not exceed the material’s elastic limit. Under larger tensions, the material does not return completely to its original condition, and under greater forces the material ruptures.

Density (specific weight is the amount of mass in a unit volume. It is measured in kilograms per cubic metre. The density of water is 1000 kg/m3 but most materials have a higher density and sink in water. Aluminum alloys, with typical densities around 2800 kg/m3 are considered less dense than steels, which have typical densities around 7800 kg/m3. Density is important in any application where the material must not be heavy.

Strength is the force per unit area (stress) that a material can support without failing. The units are the same as those of stiffness. MN/m2, but in this case the deformation is irreversible. The yield strength is the stress at which a material first deforms plastically. For a metal the yield strength may be less than the fracture strength, which is the stress at which it breaks. Many materials have a higher strength in compression than a tension.

Toughness is the resistance of a material to breaking when there is a crack in it. For a material of given toughness, the stress at which it will fail is inversely proportional to the square root of the size of the largest defect present. Toughness is different from the strength: the toughness steels, for example, are different from ones with highest tensile strength. Brittle materials have low toughness: glass can be broken along a chosen line by first scratching it with a diamond. Composites can be designed to have considerably greater toughness than their constituent materials. The example of a very tough composite is fiberglass that is very flexible and strong.

Text 11

NANOMATERIALS AND NANOCHEMISTRY

What is meant by the term ‘nanomaterial’? From an etymological standpoint, it would not appear to be very explicit. Indeed, the prefix ‘nano’ used in scales of physical units means one billionth, or 10-9, of the relevant unit. In the present case, it refers to the nanometer, or one billionth of a meter. When we use the term nanomaterial, we are thus specifying an order of magnitude of a geometric dimension. But then what is it in nanomaterials that is of nanometric dimensions?

To answer this question, we must now consider the second part of the term, viz., ‘material’. A material is matter that has been transformed or adapted to be able to fulfill some particular function. One can say that this matter has been functionalised. Many materials we use and which appear to the naked eye to be of a perfectly continuous constitution are in fact made up of grains of crystallised matter with dimensions often of the order of the micron (one millionth of a meter, or 10-6 m). This is true in particular for most metals and ceramics in common use, but it is not the case for glasses and so-called plastics, which are amorphous, or can be considered as such for the purposes of the present discussion. These micrometric grains are, of course, very small compared with the dimensions of the objects generally made with such materials. However, they are very large compared with the dimensions of the atoms that make them up. Indeed, atoms have diameters ten thousand times smaller than these grains. Consequently, there are some (104)3 = 1012 or a thousand billion iron atoms in a grain of steel of diameter 1 micron.

Forty years ago, it was realised that the properties of certain materials could be modified, improved or adapted in specific ways if, during the fabrication process, the grains making them up could be made much smaller. The first ‘nanomaterials’ were born. They can be found today in many and varied fields of application, from cosmetics, through magnetic and electronic recording devices to precision cutting tools.

2020-07-12

2020-07-12 509

509