The expansion to a small-scale processing operation requires additional investment to produce larger amounts of product in a dedicated production room. It is likely to require specialist equipment that is either made by a metal workshop in a nearby town or imported, because most rural blacksmiths do not have the necessary skills, equipment or materials to make such equipment. At this level of production, village processors are likely to be in competition with other small-scale businesses, larger companies and imported products. They need to develop attractive packaging, quality assurance techniques, and the financial and managerial skills needed to run a successful small business.

TABLE 3 Origins of some of the world's major food-processing companies

| Year | Food company |

| 1200 | Bock beer was invented in the German town of Einbeck, and is still manufactured there |

| 1383 | Lowenbrau brewery opened in Munich, Bavaria and remains in production there today |

| 1715 | French distiller, Jean Martell, began brandy production in Cognac, France |

| 1725 | The chocolate company, Rowntree, had its beginnings in a grocery store in York, UK |

| 1871 | The first margarine factory was opened by Jan and Anton Jurgens at Oss in Holland |

| 1876 | H J Heinz joined his brother and cousin to produce tomato ketchup and pickles |

| 1877 | Acream separator was invented by Swedish engineer, Carl Laval, whose company is now Alfa-Laval |

| 1884 | Swiss miller, Julius Maggi introduced powdered pea and beet soups, later to become "Maggi" Maggi cubes |

| 1899 | Coca-Cola was bottled under contract for the first time by Benjamin Thomas and Joseph Whitehead in Tennessee, USA, instead of syrup being mixed with carbonated water at the point of sale |

(Adapted from Trager 1996)

| CASE STUDY 1 Confectionery production in Sri Lanka Mr and Mrs Chandradasa live in rural southern Sri Lanka. After a short training programme in 1994, they started to produce a range of confectionery products in their kitchen using simple domestic equipment. They make approximately 1 800 sweets per week and sell them in local shops. All ingredients and packaging materials are available locally, but they are unhappy with the quality of the labels, and are seeking better ones to improve their marketing. Their main problem is that shopkeepers have the upper hand and will not pay them until the products are sold. Despite these problems, they have increased their turnover to such an extent that Mr Chandradasa has been able to leave his regular job, and they have saved enough money for a purposebuilt building for confectionery production. They have also built a 6-loaf bread oven and are baking two batches of bread per day. They hope to expand this new venture if there is sufficient demand. (Source: Edirisinghe, 1998). |

If the level of investment at this scale is too high for individual families, an alternative approach is for a group of people, such as a farmers' group, or a women's group, or a producer co-operative to operate the food processing business together (Case study 2). They invest jointly in the equipment and facilities, and market their products under a single brand name. There are many advantages to this approach including a greater willingness by lenders to make a loan if a group is sharing responsibility for the repayments, new employment opportunities for those without land, discouraging migration to larger towns or cities, and providing greater financial security and an improved standard of living to larger numbers of people.

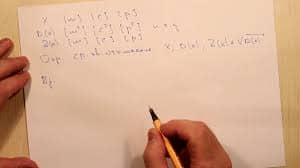

FIGURE 1 Small-scale processing. (Photo by the author)

| CASE STUDY 2 Forest fruit processing The Kalahan Educational Foundation (KEF) is a people's organization set up by tribal elders, which operates an income-generating project in the Philippine Cordillera Mountains on the island of Luzon. Traditional slash and burn farming practices have been under threat from logging companies for many years, and pressure to maintain income levels has caused many farmers to live and work outside the area. KEF took over the management of 15 000 hectares of forest reserve. They planted fruit trees and employed guards to protect the ancient forest from illegal clearances. They also set up a food processing centre to process forest fruits such as wild guava, wild grape, passion fruit and tamarind into high quality jams, fruit butters and jellies. Over 25 percent of the 540 families living in the reserve area gain significant cash income from bringing forest fruits to the factory. They are processed and packaged into glass jars bought from Manila. Fruit wastes are fed to pigs and their waste is converted to biogas to fuel the factory. The unit produces 40 000 jars of product per year and sells 85 percent of it in Manila through high-class supermarkets. They currently have 2 to 3 percent of the market and aim for 10 to 12 percent. Their customers are typically professional people who appreciate the higher quality compared to competitors' products, and for whom price is not a major issue. They are also exporting their products to Europe via a fair trading organization. (Source: Good 1997). |

Many governments promote the development of small-scale food processing enterprises because they:

· have the potential to create significant levels of employment;

· increase food security for growing urban populations as well as rural families;

· produce products that can substitute for imported foods or have export potential, and thus help reduce balance of payments problems and improve the overall prosperity of the country.

2020-10-12

2020-10-12 122

122