Bridge engineers plan their structures so that experts can easily inspect and maintain them. Once the bridge has been built, the State Acceptance Committee determines its availability status. Experts in the commission study all the documents, provide an on-site review and make visual inspection of the bridge components (fig.16.1). They examine them with geodetic devices to locate defects before they turn into a serious problem.

|

|

| a – Experts are making visual inspection | b- Bridge Inspector is assessing cable-stay condition |

Figure 16.1 Experts are inspecting a bridge

During acceptance inspection every structural element of the bridge is tested under static (fig. 16.2a) and dynamic loads (fig. 16.2b). Skilful specialists carefully examine welding and joints, which can change their initial position under an emergency load. If the structure meets the standard requirements and the acceptance documents are signed, the ownership of the bridge is transferred to the Railway and Motorway authorities or agents.

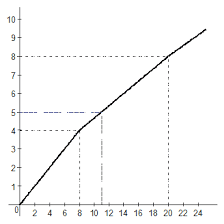

Figure 16.2 Diagram of Bridge Testing Under Static and Dynamic Loads

(схема проверки моста под постоянными и динамическими нагрузками):

a – Testing under Static Loads (проверка под статическими нагрузками);

b – Testing under Dynamic Loads (проверка под динамическими нагрузками);

1 – Superstructure (пролётное строение); 2 – Loads (нагрузки);

3 –Bridge after Deformation (мост после деформации);

4 – Vibration Amplitude (амплитуда колебаний); 5 – Period of Vibration (период колебаний)

Bridge maintenance presents many challenges even if a bridge is new. Steel bridges require a lot of maintenance in coastal regions because moisture and salts cause corrosion in the bridge components.

|

|

| a – Bridge Inspector is using Ultrasonic testing during the inspection of a bridge. | b - A regularly scheduled inspection of bridge components |

|

|

| c – Emergency state of a timber bridge | d - Routine inspection of bridge components and high-strength bolts |

Figure 16.3 Bridge Inspection

Coastal areas are also difficult environments for reinforced concrete bridges because moisture penetrates the concrete structure, deteriorates it and causes corrosion (fig.16.3a, b). Water can cause soil erosion making a bridge scour, undermine the footing and expose the piles. Substructure may be deteriorated at the water line, and suffer from cracking or impact damage caused by boats under the bridge, etc. Timber bridges can decay and be attacked by vermin (fig.16.3c). Bridges often need inspection after a flood event, onslaught of wind, fire, collision with boats or traffic accidents.

The Trans-Siberian Railway runs through permafrost areas, and bridges along this main trunk line require costly upkeep. As a lot of ice melts each summer, continual maintenance includes track leveling on railroad bridges (fig.16.4). In winter, extensive maintenance is also required to combat lifting up by frost when local displacements of 2.5 to 35 cm occur in roadbeds and bridges.

|

|

| a - Workers examine the track on a railway bridge | b – After-inspection track repair on railway bridges |

Figure 16.4 Scheduled inspection and repair on railway bridges

Detailed visual bridge inspection includes not only checking the general condition of the structure but also looking for any problems with concrete or steel materials. The inspector must assess each bridge component and identify additional testing or repairs if needed. The information is reported to supervising engineers and maintenance crews. In case of emergency, a trained, professional engineer and a repair crew immediately fix the problem. An emergency inspection is usually carried out after a flood event, an earthquake or a vehicle collision that damage bridge components.

Experts are responsible for safe bridge function, so they inspect and correct structures by running maintenance, preventive maintenance, scheduled bridge repairs, emergency repairs and overhaul. Preventive bridge maintenance is cost-effective because it provides the structure serviceability and allows avoiding expensive repairs. Construction inspectors and maintenance workers provide continuous bridge inspection throughout its service life. The rules and demands for scheduled and emergency maintenance must be observed according to the guidelines established by either “Building Specifications” or “National Bridge Inspection Standards”. Currently, there are accurate techniques for testing bridge structural integrity and safety. These techniques insure that bridges meet up to their designed specifications.

Usual bridge maintenance includes monitoring of cracks in deteriorated concrete, continual keeping the deck clean, periodical removing debris from bridge deck expansion joints, repairing apparent damage on the roadway surface, careful inspection of anchoring devices, protective painting, etc. Common maintenance concerns are welds, corroded rivets and bearings. They must be regularly flushed with high-pressure water jets to remove harmful precipitations and collection of sand or debris. The workers cleanse bridge deck, sidewalks, parapets and light stands using compressed air and mechanical devices.

A civil engineer who assesses bridge condition is a Bridge Inspector or Structural Maintenance Engineer. He can perform tests to assess the aging of bridge components because he knows the behavior of bridge elements under different stress intensities. He assesses the structural damage caused by environmental influences or human actions. The experienced bridge inspector can work high up in the air (fig. 16.1b) or even underwater. Sometimes he has to put on underwater gear (16. 5a) to monitor the bridge components below the water surface or a scour around support columns.

|

|

| a – Underwater Inspection of Bridge Components Condition | b – Painting of corroding steel bridge components |

| |

| c – Examining and replacing of corroding steel bridge components |

Figure 16.5 Bridge Inspectors assess the aging bridge components

To perform all necessary engineering supervision of long bridges, deal with bridge load capacity and column strength, do damage inspection and look for corrosion and fatigue cracking, bridge inspectors employ various assessment techniques such as Infrared Thermography, Ultrasonic or Standard Visual Inspection, etc. and use sophisticated monitoring devices and in-place sensors. To provide reliable, trouble-free operation many bridges are outfitted with monitoring devices based on acoustic emission and nondestructive evaluation (NDE) technologies. These techniques detect the acoustic reflections from growing cracks that can lead to disastrous failure of concrete (fig.16.3a).

A Bridge Maintenance Supervisor heads a crew of maintenance workers and equipment operators to inspecs short bridges and culverts. They monitor bridge safety; help the Bridge Inspector, remove and patch deteriorated concrete pavements before catastrophic failures can happen. They are responsible for removing ice, snow, slush, and storm debris. This work may result in short-term lane closures when traffic is not heavy, usually by night, but sometimes during daylight hours.

|

|

| a – Bridge maintenance personnel working in “skyboxes” | b - Bridge pier column with chipped concrete marked as the first category condition |

|

|

| с - Advanced deterioration with fatigue cracks marked as the second category condition | d - The third category of bridge condition calling for reconstruction |

Figure 16.6 General maintenance inspection is provided around the clock for assessing the categories of bridge condition

Maintenance personnel provides around the clock service locating and fixing small damage and defects: electricians inspect the navigation lights on the towers and main cables; examine light stands; b ridge painters work in "skyboxes" touching up the protective coatings. For instance, 38 painters maintaining its well-known rust-red color and 17 ironworkers examining 1.2 million rivets that are corroding under never-ending fog perform daily maintenance procedures on the Golden Gate Bridge, which is crossed by more than 100,000 vehicles each day. Painting, monitoring rust expansion and replacing corroding steel components is the primary maintenance job (fig.16.5; 16.6). Having found wear and the exact anomalous zones in bridge components, a maintenance crew fills in the forms and keeps detailed and accurate records of bridge inspections and testing. They also keep a written record of wear-out failures, which need general overhaul.

The assessment categories of bridge condition are ranging from zero to the third category. The condition marked as zero category is the standard bridge condition when no problems are noted. The first category means that nearly all bridge elements are safe but the structure may have minor damage and failures such as cracking, spalling or scour. The workers repaire this damage during running maintenance (fig. 16.6b).

The second category means that the primary structural components are suffered from advanced deterioration with fatigue cracks in steel segments and shear cracks in concrete that may result in a pothole.The bridge or the component under suspect must be closely monitored, and correction action may require immediate repair or complete overhaul (fig. 16.6c). The third category means imminent failure that calls for reconstruction or complete replacement, and the bridge is considered to be out service (fig. 16.6d).

Maintenance cost may influence the bridge type selection. Concrete bridges usually require the least maintenance, which is crack sealing for preventing and reducing rebar corrosion. Timber structures are also an easy bridge type to repair. For instance, the workers replace decayed or broken planks with no difficulty and quickly fasten sound planks by metal fasteners. Access for inspection and maintenance is among the priorities of bridge engineering.

2015-04-17

2015-04-17 596

596