Большие эксплуатационные затраты; выявление усталости металла; гнить; дефект материала (раковины); досконально; изнашиваться; коррозия; ледоход; неисправность, нарушающая работу других элементов системы; неприглядно; нержавеющая сталь; оседание грунта; ослабление болтов; паводок; подмыв опор; покраска; разрыв сварочного шва; ржаветь; скол; смещение опор; трещина; удаление грязи, песка; усадочная раковина; эксплуатация.

All bridge types have their own peculiarities, and maintenance crews have to consider them. In the case of short span bridges (between 2 and 6 m) made out of timber, the most complicated maintenance problems are ice drift and water flooding. Bridge scouring caused by rushing water may result in support displacement. In addition, timber can decay and suffer from fire.

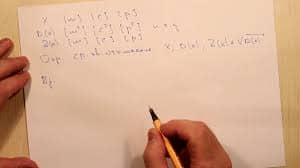

Metal structures also demand appropriate care because their elements and joints become rusty. Salt precipitation from seawater has an influence on steel components of the bridge enhancing corrosion. That is why metal bridges need painting or some other surface treatment. Stainless steel is too expensive. High-strength bolts and rivets weakening, welding damage and other active faults call for continual and qualified inspection. The places where older steel parts are connected need steel fatigue inspections by ultrasonic testing to check for cracks.

Reinforced concrete bridges do not require heavy maintenance cost if they are built without any engineering faults. However, fractures, flawing and cracking, concrete spalling and reinforcement corrosion, voids and delaminations, cissing and shrinkage cavities may frequently appear in concrete structures. The most hazardous defects, especially dangerous in supports, may appear when concrete hardens. Inspectors use ultrasonic teststo determine cracks that are undetectable to the human eye. In addition, the displacement of supports is a serious threat to the bridge’s foundation, especially in the case of soft ground.

Culverts need careful inspection, cleaning and such work as desilting and desanding before each flood. Some culvert sections can displace due to soil settlement in the embankment.

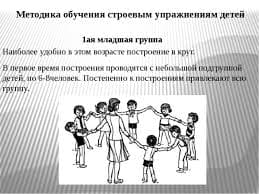

During inspection, the experienced, professional engineers and inspectors must rigorously examine each bridge component, and identify any maintenance work for ensuring safe travelling. The inspectors load a special truck with concrete blocks and attach instruments to the bridge. The truck drives across the bridge while the instruments record the structure movements and measure the bridge load capacity. Minor rusting on certain bridge components or chipped concrete may be the natural process of bridge aging that does not affect bridge safety, though the structure may look unsightly.

Inspectors may remove small samples of concrete or steel from the bridge for conducting tests using laboratory devices to check the strength.

2015-04-17

2015-04-17 347

347