The fuel systems of diesel and carburettor engines differ in principle.

IN THE CARBURETTOR ENGINE, the combustible mixture of required composition is prepared from air and fuel in a special device - carburettor - and is then delivered in desired amounts to the individual cylinders of the engine.

In tractor starting engines, fuel is fed by gravity from tank to carburetor through combination fuel filter and sediment trap.

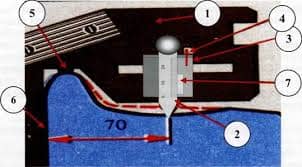

In automobile carburettor engines, fuel is drawn from tank through combination fuel filter and sediment trap and a fuel line by pump which delivers it to carburettor. On the intake stroke, atmospheric air is drawn into the carburettor through air filter (cleaner) where it is cleaned of foreign matter. In the carburettor, the incoming air is mixed with finely atomized fuel and then passes into intake pipe (manifold). The preparation of the air-fuel mixture continues in the intake pipe where the fuel evaporates and mixes more intimately with the air. The process ends in the engine cylinders during the intake and compression strokes. After the combustible charge has burned, the burnt gases are expelled into the atmosphere through the exhaust pipe (manifold) and muffler.

The automobile carburettor engines operate mainly on gasoline (petrol). To obtain a satisfactory engine performance with reasonable fuel economy, the gasoline fuel must possess adequate volatility and knock resistance.

Combustion knock also is called detonation. Detonation is an extremely rapid, explosion-like combustion of the fuel in the engine cylinders. The engine must not be allowed to knock, for this condition is attended by heavy impact loads on the pistons, piston pins, and crankshaft main and connecting rod bearings and leads to local overheating of the engine components, burning of pistons and valves, smoky exhaust, loss of engine power, and increased fuel consumption. The onset of detonation is related not only to the knock resistance of the fuel, but also to the engine speed and load conditions, carbon deposition on the pistons and the cylinder head, ignition timing, etc.

The knock resistance of gasoline fuels is evaluated in terms of their octane number, or rating. The octane number of a fuel is determined by comparing its knock resistance with the knock resistance of a blended reference fuel of known octane rating. The reference fuel is a mixture of two fuels: heptane and isooctane. Heptane has a low knock resistance and its octane rating is arbitrarily taken to be zero. On the other hand, the knock resistance of isooctane is high, and its octane rating is arbitrarily set at 100.

The octane number of a fuel is defined as the percentage by volume of isooctane in such a mixture of isooctane and heptane as is equal to the test fuel in knock resistance. For example, if a mixture of 76% isooctane and 24% heptane is equal in knock resistance to the test gasoline, the octane number of the gasoline will be 76. The higher the octane rating of a fuel, the higher its knock resistance.

2015-06-28

2015-06-28 843

843