| Dimensions in mm | Quality grades | |||||||||||

| Over 3 to 5 | 2.5 | |||||||||||

| Over 6 to 10 | 2.5 | |||||||||||

| Over 10 to 18 | ||||||||||||

| Over 18 to 30 | ||||||||||||

| Over 30 to 50 | ||||||||||||

| Over 50 to 80 | ||||||||||||

| Over 80 to 120 | ||||||||||||

| Over 120 to 180 | ||||||||||||

| Over 180 to 250 |

Possible errors of surface dispositions are non-perpendicularity relative to a base, misalignment, non-symmetry, non-parallelism.

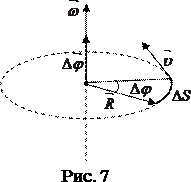

For shafts it is necessary to use total tolerances that take into account tolerance of shape and tolerance of surface disposition: radial run-out that allows for non-rounding and misalignment and end-play that takes into account non-flatting and non-perpendicularity.

The magnitude of radial run-out  depends upon the peripheral speed and is determined according to table 14.3.

depends upon the peripheral speed and is determined according to table 14.3.

The magnitudes of end play  may be found according to table 14.4.

may be found according to table 14.4.

Table 14.3

2015-08-21

2015-08-21 265

265