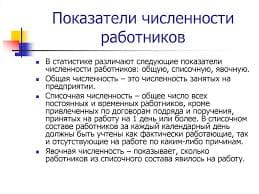

______________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

INTRODUCTORY ARCHITECTURE

ARCHITECTURAL DESIGN OF A BUILDING

Orientation and Surveying the Building.—Before beginning construction of any building it is necessary to consider several problems connected closely with the lot where the building is to be erected. Some of these problems are as follows:

1. Soil.—Soil is a very important problem in the building of any house. The land may have a sufficient depth of rich top soil, but beneath it may be a ledge of soil rock, which will make the excavation for a basement very expensive especially in climates where the footings must be carried down below the frost line.

2. Transportation.—The problem of transportation is the most important one during the whole period of construction on the building site. One must see if there is a sufficient means of erecting ways for bringing up the materials and men for construction work.

One must also see if there is a sewerage line, water supply line, gas line, the electric power line, and how all of them can be used.

3. Surveying.—A survey is a plan of a piece of land showing its exact dimensions and levels, the lot boundaries with relations to adjacent streets and lanes, the location and the levels of existing sewer and water mains, electric light, gas services, etc.

Styling of a Building. — When all things mentioned above, are carefully considered, another point must be kept in mind. This is the '-style" in which the building is to be planned or, in other words, its exterior appearance.

If we have to design a house, there is a number of practical considerations which will have an effect upon the design of a house. Some of these are as follows:

1. Height of first floor above ground.

2. Ceilings' heights. The height of the ceiling, that is clear height from floor to ceiling, is a matter to be determined by the designer.

The old opinion was that high ceilings made houses airy and cool in summer and rooms were often made nine and even ten feet high. Now it is a tendency to make the ceiling lower.

Porches, entrances and other details are very important things connected, with the styling of a house.

Footing and Foundations.—Now we shall consider the separate parts of a building, beginning with footing and foundations. The extra thickness where the wall rests on the ground is called a footing. The extra thickness for the wall at the bottom might be obtained by making the walls thicker as it increases in depth below the surface of the ground.

The method of forming footings is to step the foundation wall out of the bottom on both sides until the area of ground covered the bottom of the foundation considered to be sufficient to support the load imposed upon it by the wall.

The size of footing; depends upon the load imposed on the soil per running foe, of wall by the loads on the floors, as well as the weight of the materials of which the floors and walls are composed.

Foundation Walls.—The first thing which must be kept in mind when the foundation walls are in construction is that the special precautions need be taken in order to ensure a dry basement at all times. When dampness or standing or running water conditions exist in the soil surrounding the basement walls, some methods must be employed to prevent the moisture from finding its way into the building. There are several methods to prevent the foundations from dampness: drain tile, plaster and pitch, felt, concrete mix.

Types of Materials for Walls, Floors, Partitions.—The materials which are mainly used for house building are wood, plaster, brick, stone, veneer, concrete construction. Pleasing effects are often obtained by treating the exterior of a house in two different materials, such as stone and wood or brick and wood or brick and stucco.

Designing Elevations. – An elevation is a drawing that shows one side of a building as it would appear if the observer could look directly at every square foot of its surface at once and could not see any of the other three sides at the same time. Since most houses are rectangular in plan, there will be four elevations.

Every part of the outside of every exterior wall can be shown on one or other of these four drawings, which are to a scale, usually of one-quarter, one-eighth inch to the foot. All the door or window openings and other features of constructions which are on the outside surface of the exterior walls can be shown on the elevations in their true dimensions as regards width and height.

Other Constructions.—The first houses were merely shelters built for the purpose of protecting their owners from weather and therefore were very simple—a roof to keep off the rain, and the walls to keep out the wind.

In the beginning there were no windows. A little later each house had its fireplace and a masonry chimney. For many years, even centuries houses were built without any conveniences. There was no plumbing, no water supply, no heating system, no electric light. Very gradually a change came about, especially in cities.

First there was plumbing, running water in the kitchen, then hot water, then fully equipped bathrooms.

The latest thing is air conditioning and comfort cooling. To the work of the carpenter, to mason, the plasterer and the roofer, has added the work of the so called mechanical trades: the plumbers, the steam-fitters and the electricians. The requirements of these mechanical trades must be provided for in the planning.

Lines of heating and water drainage pipes and air ducts must run through the house, and, as they are not ornamental, arrangements must be so that they can be concealed in the walls and floors.

The same is concerned of the electric wiring. For a long time people were so proud of their heating system that they did not mind looking at the radiators, but now the central heating is commonplace; many people dislike their ugliness and want them concealed in the walls.

Now the architect who makes plans for a house must fort see what is necessary for all the piping and wiring and must make suitable allowance.

ARCHITECTURE OF A HOUSE

I. Styling of a House.—When a house is to be built there are a number of things which should be given careful thought before the work is started and even before the plans for the building are drawn.

Among these may be mentioned the selection of the lot on which the dwelling is to be built, the position of the house and garage on the lot with reference to the streets and the position of the different rooms with reference to the four points of the compass—North, South, East and West. At the same time when these things are being considered, another point must be kept in mind, that is the "style" in which the building is to be planned or, in other words, its exterior appearance. This decision should be made before plans for the house are started. The important question is also how much money can be spent on the building.

II. Designing Elevations. — An elevation is a drawing showing one side of a building. Since most houses are rectangular in plan, there will usually be four elevations. All the door or window openings and other features of construction which occur on the outside surfaces of the exterior walls can be shown on the elevations in their true dimension (to scale) as regards width and height. The elevations are practical working drawings, the purpose of which is to give to the workmen the information necessary in order that they may first set a price on the work to be done and then carry it out properly after the contract has been awarded.

The floor plans are also prepared for this purpose. The elevations must agree with the plans in giving the general dimensions of the house and the location and width of the door and window openings on each floor and other features such as balconies, porches, terraces, bay-windows, etc. Taken together the plans and elevations give the length, width, and height of every part of the house in such a way that when the various parts are built to these dimensions, they will form the completed building just as the designer saw it in his mind when he was making the drawings.

The choice of style of elevation depends upon several factors. Some are guided primarily by cost, others by desire for a certain style. Most people are concerned with the arrangement of rooms—the floor plan—and will let the exterior of the house be modified as necessary to conform to the floor plan selected. Elevations for houses in the Modernistic Style are entirely different from those for traditional houses. They usually have extremely large window areas, extending to and around the corners of the building. This with the flat roof, makes almost box-like appearance, which seems strange to one accustomed to the traditional style.

Material for Elevation.—The choice of material is governed by the style and by the cost. Many styles can be worked out in any several materials or in combinations of two or three. Brick and siding, shingles and siding, brick and stucco, wood, plaster, stone and concrete—all can be handled in interesting fashion. The materials used for roofs are shingles, slate or tile. Tile and shingles are inmost cases the most expensive roof materials, slate is less costly. For wall construction, brick is cheaper than siding, and brick cheaper than stone, in most localities.

The elevations show the heights of all openings in the outside walls and the height of the window and door sills above the finished levels of the different floors. Exterior doors are apt to be 2 feet 8 inches or 2 feet 10 inches wide and 6 feet 8 inches or 6 feet 10 inches high. The larger sizes are to be applicable to the front entrance door and the smaller sizes to the rear entrance door. There is a danger in making exterior doorway too narrow, because furniture and other things must be carried through them. The front entrance door should be of a good design in keeping with the style of the house.

Window openings can be of various sizes to suit the ideas of the designer. There are two kinds of windows used in houses. There are the double-hung and casement windows. The first consists of two counterweighted sashes sliding up and down; the second has one or two sashes hinged at the side and swinging horizontally in or out. There is also a bay window which is seldom seen today. Wooden shutters or blinds are often used on some of the windows of a house. Sometimes they are solid and sometimes slatted. An up-to-date house must contain one or more bedrooms for sleeping, a kitchen for preparing the meals, a dining room, a utility room for laundry and storage, and a living room for reading, writing, entertaining visitors and so forth. In addition to these rooms every present-day house contains a bathroom and may include a recreation room in the basement, and a den or study.

Bedrooms. Bedrooms should be so arranged in the house plan that each one will have cross-ventilation, that is so, that the fresh air can enter the room through one window and the foul air escape through another. This should be accomplished in such a way that the air will not blow directly over a bed. To meet this requirement, it is necessary that at least two of the walls of each bedroom be outside walls with a window. This means that each bedroom must be a corner room. Another requirement is that the bedroom door should open out of the hallway or a corridor, never out of another bedroom. Besides the entrance door, there is always one closet door, and a door to a bathroom.

Kitchens.— In a properly planned kitchen there are three principal centres of activity, as follows:

1. the preservation and storage centre,

2. the cooking and serving centre,

3. the preparation and cleaning centre.

These can be comfortably accommodated in a kitchen 7 feet 6 inches by 10 feet.

Dining room.—Such a room should be next to the kitchen with only a partition between them. It should be at least 11 feet by 12 feet and preferably 12 by 15 feet in size. Dining room should be well lighted by a large window or windows facing so as to let the morning sunshine come into the room.

Living room.—The room which is used more than any other during the afternoon and evening is the living room. This room is also the one most often seen by guests, and may be said to be the show room of the house. For these reasons the living room is usually the largest room and the most handsomely furnished. In the smaller houses it is used by all members of the family as reception room, library, music room, study, entertainment room, and play room, and at times it becomes a spare bedroom. The room should be as large as can be allowed, ranging from 12 feet by 16 feet up to 20 feet by 26. The entrance should be of good width and centrally located. Often there is no door, but only a door opening which may be closed by means of curtains or by folding or sliding doors.

Utility room. — Equipment such as the heating plant and laundry tubs are in a small room (about 7 feet by 8 feet) called a utility room, near the kitchen on the ground level. Laundry equipment should be located with thought for efficiency and light, as some of the hardest work in the house is done in this room.

Bathroom.—Any present-day house has at least one bathroom. The three plumbing fixtures which an ordinary bathroom usually contains are the bathtub, the water closet, and the wash basin.

Mechanical Consideration.—The first houses were built for the purpose of protecting their owners from the weather, and therefore were very simple—a roof to keep off the rain, and walls to keep out the wind. When the first houses in cold climates were constructed, it became necessary to provide for the fire and get rid of the smoke. At first the fire was in the middle of the floor, and the smoke found its way out through a hole in the roof. Later each house had its fireplace for the fire and a masonry chimney. For many centuries houses were built with no conveniences. There was no plumbing, no water supply inside the house, no heating system, no electric light. Very gradually a change came about. First there was plumbing, running water in the kitchen, then hot water, then equipped bathroom. Then there was heating by means of a furnace or boiler located in the basement or cellar. Soon there was gas for lighting and cooking, and after that electric lighting. The latest thing is air conditioning and comfort cooling.

In a present-day house lines of heating and water and drainage pipes and air ducts must run through the house, and, as they are not ornamental, arrangements must be so that they can be concealed in the walls and floors. The same is true, to some extent, of the electric wiring. A soil pipe can be concealed by making a section of a partition 8 inches thick and running the soil pipe in it. The purpose of ducts in houses is to convey warmed or cooled air to the various rooms.

Plumbing.—For many centuries plumbing was unknown, except in the places and houses" of the great wealthy. Amid the ruins of some cities of ancient Roman times evidences have been found of the use of piping systems to a very limited extent in private houses and to a much greater extent in connection with public bathhouses. Step by step during a long period of years modern plumbing has been evolved.

Water-supply piping.—Water is brought into house from the street mains (water pipes) through pipes. The branch pipes supplying water to a bathroom and lavatory will be ¼ inch for both cold and hot water. A branch which supplies a kitchen sink and laundry tub will be ¾ inch for either cold or hot water. Water-supply pipes inside houses are made of galvanized iron, wrought iron and of brass.

Drainage.—Drainage pipes outside of the house itself, that is, between the house and the sewer in the street, are called the house sewer. They are usually of glazed vitrified tile, but if the ground on which the sewer is laid is not absolutely firm and solid, cast-iron pipe should be used, as it is much stronger than tile, which is liable to be broken by any settlement. Drainage pipes inside the house in the basement or underneath the basement floor are called the house-drain. Drainage pipes should be of cast iron.

Electrical work.—The light distribution may be direct, semi-indirect or indirect or it may be some combination of these. Direct lighting is the type in which most or all of the light is directed downward. This type gives the most light and is the one usually found in older houses. Direct lighting is not uniformly distributed over a room. Indirect lighting is the type where all the light is directed upward to the ceiling by means of inverted reflectors and the lamps cannot be seen from the floor.

Semi-indirected lighting fixtures direct most of the light to the ceiling, but allow some of it to be projected downward. In almost any room there are some local areas where special activities, such as reading or writing or sewing, are carried on or where special tasks, are performed which require an intensity of light much higher than the general lighting. These all lighting will consist of a combination of general and localized illuminations. In a living room there will usually be a ceiling fixture or wall brackets for general lighting and a number of portable lamps plugged into convenience outlets. In a dining room, since the table is the centre of interest and is in the middle of the room, one light fixture in the ceiling over the table is usually sufficient, and furnishes the general and local lighting at the same time. In the kitchen a central ceiling fixture for general lighting and lights over the sink and range for local needs are usually required. A bedroom can be served by one ceiling fixture with portable lamps on bedside tables and on dressing table. The requirements of a bathroom can be taken care of by two lights, one on each side of the mirror, but a central ceiling fixture in addition is frequently wanted.

Heating and Air Conditioning.—People are comfortable when they are neither too cold, nor too warm and when the air about them is neither too dry, nor too damp and is not stuffy or dusty. To bring about these desirable conditions the heating or air-conditioning apparatus must be capable of maintaining the following conditions inside the house, whatever the conditions outside may be.

For adequate heating when it is cooled outside the heating plant, including the necessary ducts, registers, piping, radiators, etc., must be able to keep all the rooms at 70° Fahrenheit, even if it is 20 or 30 degrees below zero outside.

To avoid stuffiness, the air should be given a certain amount of motion. Under winter conditions this must be sufficient to distribute the heat uniformly throughout the rooms. It must not be too cold at the floor, or too hot at the ceiling. A stove causes the hot air around it to rise up toward the ceiling and cooler air to flow toward the stove. A radiator acts in this respect like a stove. Warm-air registers bring heated air into a room with a certain motion or velocity which imparts movement to the air already in the room. An outlet for this air should be provided in order to have good ventilation. In summer-time much greater air motion is needed, enough to change the air in a room completely from three to ten times per hour. Sometimes a fan is placed in the attic to blow the warm air out and to cause the cooler night air to flow in through open windows. When this is done, air in the house can be expected to be changed completely every two or three minutes. When air is brought into a house from outside, heated in a furnace and distributed through all the rooms, it ought to be cleaned by passing it through “filters” before it enters the furnace. These filters must be capable of straining out from the air all dust, soot, pollen and other impurities. Filters should be so installed that they can be easily replaced. Cleaning the air this way prevents the dirt from entering the house and soiling the walls and furniture.

Cooling.—In. summer, or in hot climates, cooling of the air in a residence is desirable and is often clone, special refrigerating equipment being installed to do the job. The air in the rooms should be maintained at a temperature not more than about fifteen degrees lower than the thermometer readings outside at all times, in order to prevent discomfort from too sudden a change for persons going into or leaving the house. This cooling must for comfort be accompanied by movement of the air and regulation of the humidity, so that a clammy feeling will not be experienced.

ARCHITECTURE OF A HAHOAR

Materials.—The aluminum alloy HE-10 is used for the structural sections. This alloy is the one most widely used in structural work on account of its good mechanical strength properties, high resistance to atmospheric attack and ease of fabrication.

Loading conditions. — In addition to dead loads from the covering and structure, a snow load of l0 lb/sq. ft. was taken. To allow for the addition of lights, sprinkler systems, an extra load of 2 lb/sq. ft. was also taken.

The main portal frames have also been stressed to withstand 30 cwt. point loads at four positions along the lower boom to allow for a light runway being added.

The wind forces are based on a wind velocity of 65 m.p.h. at an effective height of 50 ft. resulting in a pressure of 14 lb/sq. ft. structure. The main structure consists of 12 portal frames at 30 ft. centres, spanning 217 ft. between pinned bases of welded steel, giving a clear span of 200 ft. between the inner roof legs. The roof is of north-light construction. Daylight requirements are fulfilled by incorporating twelve continuous runs of glazing 9 ft. 3 in. deep using aluminum alloy glazing bars and -^in. wired cast glass in 24 panes. The south slopes are covered with aluminum roof decking covered on the outside with — in. insulation board, bonded to the deeply corrugated decking with hot oxidized bitumen, the whole being waterproofed with two layers of bitumen roofing felt with mineral finish to the capping sheet. The hip slopes are also covered in the same way.

Sheeting.—The east wall is sheeted with corrugated aluminum alloy sheeting treated by the Alochrome process. This wall is lined with 3/16 in. thick asbestos-wood board and sunfoil reflective insulation fixed by extruded aluminum T-sections. The bottom 9 ft. 4 in. is of brick. The west wall is sheeted only above the roof level of the annex.

Doors.—The main sliding and folding doors, which are of the Esavian type, give a clear opening 200 ft. wide by 44 ft. 9 in. high. Two sliding and folding doors, 12 ft. wide and 15 ft. high are incorporated in the east wall.

Erection.—The lifting of the portal frames was given careful consideration so as to obviate any undue lateral distortion, the vertical legs of two frames being first erected and braced together laterally and in the plane of the portal frame, whilst the roof portion was lifted into position by slings from four points about 40 ft. apart, each pair of slings.being suspended from lifting beams. Although the weight of the roof portion is only about 4.5 tons, two 5-tons hand cranes are used to provide the 60 ft. length of jib required for the operation. Whilst the vertical legs being erected, the roof girder was assembled in two halves. The two assemblies were then brought together along the centre line of the portal frame, matted and then lifted into position. The assembly took only two days per frame, and the lifting operation was completed in three hours.

Foundations. — The portal frame bases are secured to the reinforced concrete foundation block by means of four 2 in. diameter holding down bolts designed to resist shear force and uplift.

SUPPLEMENTARY READING

RESEARCH ON CEMENT AND CONCRETE

The use of reinforced concrete on a large scale called for increased research. Of great theoretical importance were the works of Academician A.A. Baikov, developed in recent years by Academician P.A. Rebinder, on the setting and hardening of cements, and research was conducted by K-S. Zavriev (Member of the Academy of Sciences of the Georgian S.S.R.), and Moscow scientists, including Professors'B.G. Skramtayev, N.A. Popov, and others, on the constitution of cement and on concrete mixtures.

Prior to 1931 Russian Portland cement concrete generally had a compressive strength of 160 to 200 kg. per square centimeter (2270 to 2840 lb. per square inch). By the middle of 1932 this had been increased to 275 to 400 kg. per square centimeter (3900 to 5680 lb. per square inch). With the cement of 1926 it was common to use 350 to 400 kg. cement per cubic meter of concrete (590 to 756 lb. per cubic yard), but in 1932 it was not permitted to use more than 250 kg. of cement per cubic yard (420 lb. per cubic yard) in concrete with a compressive strength of 110 kg. per square centimeter (1570 lb. per square inch.). Today concrete with a compressive strength of 700 kg. per square centimeter (10,000 lb. per square inch) is obtained.

Ordinary and high-strength Portland cements, Portland blast furnace cement, high-alumina, hydrophobia, and plasticized cements are available. With the aim of reducing the period of curing of precast units the production of quick-setting cement has started. Precast concrete structural members are made with compressive strengths up to 500kg. per square centimeter (7140 lb. per square inch).

Over the greater part of Russia the winters are severe and, in order to carry on concreting all the year round, it was necessary to study the problem of concreting in cold weather. With the use of the so-called "thermos" method and by steam and electric heating the winters are no longer an obstacle. In recent years use has been made of reinforced concretes with high salt content which will harden at temperatures as low as 25 С below zero. Important research on concreting in winter conditions has been carried out by Professor S.A. Mironovand B.G. Skramtayev, V.N. Sizov, I. G. Sovalov, and others.

Concrete made with lightweight artificial or natural aggregates are much used, and are made by processes devised in Russia. by Professor N.A. Popov and by specialists in Georgia and Armenia where lightweight natural aggregates are available in the form of pumice and tuff. Lightweight concretes containing either natural or artificial lightweight aggregates are used for the manufacture of load-bearing members such as floor and wall panels.

From 1932 onwards cellular concrete made with cement and a foaming agent has been widely used. Thanks to the researches of I.T. Kudryashov, cellular concrete is made from a mixture of cement and ground sand steamed under pressure in an autoclave. In 1939 the first factory for the production of cellular concrete was built in Chelyabinsk, and products are made with autoclaved cellular concrete, cellular silicate concrete, clinker concrete, and so forth, with a density of up to 1200 kg. per cubic meter (78 lb. per cubic foot) and a strength of up to 150 kg. per square centimeter (2130 lb. per square inch).

The production of acid-proof concretes has been developed, and extensive research is now proceeding on the corrosion of concrete. Professor V.M. Moskvin has established the possibility of using concretes in different aggressive environments and methods of protecting concretes against such aggressions. Dr. K.D. Nekrasov has devised methods of producing refractory concretes capable of withstanding a temperature of 1200 deg. C. Such concretes, incorporating Portland cement, high-alumina cement, and soluble glass, are used for the foundations of blastfurnaces and for purposes for which refractory ceramic tiles are used. Under the direction of Professor V.V. Mikhailov, a strongly-expanding cement has been produced which quickly acquires great strength, and when subjected to heat expands greatly and increases the bond between the concrete and the reinforcement.

In most cases concrete is mixed at automatic plants and consolidated by vibrators and vacuum apparatus. At the Kuibyshev hydroelectric power development 7,840,000 cu. yd. of concrete will be placed, and at the Stalingrad power plant, 9,139,000 cu. yd. Researches on methods of placing concrete have been conducted by Dr.V.S. Shestoperov, Dr. A.E. De-sov, O.A. Gershberg, and others.

In recent years considerable improvements have been made in the quality of steel reinforcement, most of which is mild steel. The application of welding to reinforcement is an important development. In a number of plants machines 'have been installed for the production of reinforcement cages for columns. These machines, which are 160 ft. long and are remotely controlled, automatically measure and cut the bars, straighten them, place them in the required position, and weld the transverse bars to the longitudinal bars. The machines are operated by three men, and a cage for a two-story column is made in from six to seven-and-a-half minutes. Working two shifts a day, one automatic machine produces about 45,000 column cages a year.

PRECAST STRUCTURAL MEMBERS

In connection with the extension of construction work in the U.S.S.R., the need arose for the increased use of precast reinforced concrete, and the production of precast concrete is to be increased from nearly 2,500,000 cu. yd. in 1954 to over 13,000,000 cu. yd. in 1957; the rate of progress shows that in 1957 nearly 17,000,000 cu. yd. will be produced. This made it possible in 1955-56 to erect nearly 70,000,000 sq. ft. of industrial premises and 156,000,000 sq. ft. of dwelling houses with the use of precast members. For the manufacture of these structures, 602 factories are to be built in the year 1955-56.

Highly-mechanized production is profitable only when accompanied by a large output, and this calls for limitation of the number of different elements to be produced at each factory. For this reason standards are being prepared for storey heights and spacing of columns and beams in industrial premises and dwelling houses, and many types of structures with standard dimensions have been designed. In some factories the members are made on conveyors. In Moscow two new plants, each with a capacity of 156,000 cu. yd. a year, are in operation producing floor and wall slabs for multiple-storey residential flats, while the other units required for these structures are made at other factories in Moscow. Similar plants with capacities of 156,000 or 78,000 cu. yd. a year are being built in other large cities. In cases where it is required to produce parts for both industrial structures and houses, factories are being erected with differing capacities and with means of quickly changing production from one type of unit to another. Factories are also being built to produce large clinker blocks, as well as dense concrete and cellular concrete wall and floor slabs. The raw materials include fine sands, granular slugs, clinker from power stations, and other local materials.

Standard designs have been prepared for different classes of structures, a few examples of which follow. For single-storey industrial premises the spacing of the columns is specified as well as the height. The columns are precast, and are of rectangular, T, and I cross sections. Prestressed columns are also used. For the roofs of industrial premises, slabs 20 ft. by 5 ft. or 20 ft. by 10 ft. are recommended. Where thermal insulation is required the edges of the slabs are of dense concrete and the remainder, of cellular concrete. For the roofs of structures with bays of 40 ft., 50 ft., and 60 ft., beams made of separate blocks prestressed together with steel bars are recommended. Beams of this type with I-shape cross section are used. Various types of trusses, crane girders, and so on, have been standardized in reinforced and prestressed concrete. Standard types of suspended floors have been prepared for several types of structures. These include insulated panels up to 36 sq. yd. in area, with prestressed ribs, hollow panels with circular and oval cores, and solid panels of lightweight concrete; the prestressed panels are the design of Professor V.V.Mikhailov. Use is made of standard bridge beams of prestressed concrete by the method of A. P. Korovin. The beams for one railway are in lengths of 90 ft. to 155 ft. and taken to the site by rail. Reinforced concrete segments were used for lining the tunnels of the Moscow underground railway, and concrete pressure pipes are extensively used.

Precast reinforced concrete structures in Russia. are based on extensive standardization of members and of methods of manufacture, the standardization of joints, welding of the reinforcement and the joints, and on the use of high-strength concrete. The design of concrete and reinforced concrete and the application of this material are being rapidly developed and are steadily growing. This progress on concrete and reinforced concrete facilitates the fulfillment of the vast amount of work that is proceeding in all branches of construction in order to improve the living standards of the people and to cater more fully for their material and cultural needs.

NEW FOAM MATERIALS USED IN BUILDING CONSTRUCTION

In West Germany, there is at present a development in the field of foam materials, especially those destined for building construction. In contrast to rubber-based lexes foam, the new foam materials are wholly synthetic. Sheets made on synthetic foam materials can be used just as easily as the foam rubber sheets already in use for about thirty years.

Upholstering or insulation. Thus, foam plastics is a material well suited for upholstering where shapes profiles of this material have come into their own of late. Costs have been reduced by the use of combinations of foam plastics and lexes foam. A new foam material, known as "Poresta", and distinguished by its exceptional lightness, has been created for building and thermal insulation purposes. This material does not absorb moisture and is therefore particularly well suited for insulation purposes; it is proof against fungi and rotting. The material can be cut with a sharp knife, ground and milled, and can be glued by means of special adhesives. Poresta sheets are at present pro ducked in standard dimensions of 500x500 mm. and thicknesses between 10 and 150 mm., with a density between 0.025 and 0.03. The range of applications is great. It includes building materials for thermal and sound insulation, footfall sound insulation, sandwich type panels, etc., materials for special heat and cold insulation purposes (refrigerators, etc.), furniture and doors, decorating materials, e.g., for shop windows, etc. The material is elastic, very light, it can be boiled and it can be sterilized.

It is indifferent against cement mortar and can therefore be used as an insulating material in concrete walls and ceilings, etc. After trials extending over many years it has now become possible to produce a very light and flexible foam material from urea resins which consists, to the extent of 99.7 per cent, of air-filled cells and is therefore an excellent material for purposes of thermal insulation.

Flexibility. This material, known as "Spumalit", can be bent at angles of 90° and more without breaking. It is now possible to produce, from this material, endless tapes of between 1 and 20 mm. thickness. Because of its extremely low density of no more than 3 to 4 kg. per cu. m. "Spumalit" has a resilience hitherto unknown with insulating materials of this kind. The material is not affected by temperatures between -50°C., and +120°C., and is proof against water, oil, alcohol, hydrocarbons, diluted alkalis and acids. It is used increasingly as a thermal and acoustic insulating material in building construction and in other spheres.

NEW PRINCIPLES IN CONCRETE BUILDING CONSTRUCTION

On the occasion of two-day conference convened at Stockholm in November, 1956, by Sweden's leading housing association, Problems of concrete building construction were discussed by leading experts in this field.

Cheaper than brick. It has been found that thin bearing walls of concrete are cheaper than thick brick walls, especially if the gain in utilization space is taken into account. This even applies to 6 in. concrete walls with plaster, compared with 8 in. brick wall. It applies even more to the new technique whereby at least the secondary walls are no longer rendered. It has, moreover, been found that the latest specifications for the sound insulation of internal walls can be satisfied with unrendered concrete walls of not more than 12 cm. (4¾ in.) thickness.

Reduced thickness can also be applied to structural floors. In recent years H.S.B. have been using concrete floors of no more than 20 cm. (8 in.) thickness which, while being more economic in terms of material, cost and space requirements, are still satisfactory also as regards acoustic insulation, since the problem of insulation against impact noise has been solved by using special sound insulation between structural floor and the flooring proper. One drawback with such thin floors is the difficulty of accommodating pipes.

Thermal insulation. Reverting to the design of external walls, the Swedish experts make a special point of stressing the importance of adequate thermal insulation which may have the effect of central heating and hot water. To provide effective thermal insulation is easiest with walls which have no bearing function so that their design can be almost exclusively governed by insulation considerations.

Saving in weight. The present-day trend, in Sweden, towards thin unrendered concrete walls and thin structural floors has already entailed a certain degree of simplification and mechanization of building construction. Further progress is still somewhat impeded by the fact that there has been no corresponding simplification or standardization in the design of plumbing installation. Even so, the savings in volume and weight, and hence in cost, effected by resorting to thin-walled, thin-floored concrete buildings are already considerable. With a normal three-storey block of flats, they amount to a saving in volume of about 8 per cent and to a saving in weight of as much as 23 per cent (corresponding to about 700 ions). This must be regarded as a most satisfactory result of the new methods.

VERMICULITE A VALUABLE BUILDING MATERIAL

Among the materials which are new or almost new to the building industry in Great Britain since the war is Vermiculite. The increase in its use over the period has been fairly rapid "which is perhaps understandable when its valuable properties are considered. It is lire proof and has very useful thermal and sound insulation qualities. So far its chief uses have been as a loose fill and as an aggregate for concrete and plaster. There arc prospects that it will soon be mixed with other materials. The possibilities of its use are fairly extensive.

Vermiculite is a hydrated form of mica, extensive deposits of which are found in Montana, U.S.A., and South Africa. It exfoliates or expands in commercial practice from its raw state to about 12 times its original volume. The exfoliated material forms a cellular structure which gives it excellent insulating properties while it will withstand temperatures of up. to 2,200 deg. F., with no change in its properties and even above that temperature it will in no way contribute to the spread of fire. With the tendency to build higher, where firefighting is an important question, the fireproof qualities of Vermiculite are especially important. It does not harbor vermin or fungi.

The thermal conductivity of Vermiculite is 0.45 B.T.U. and its thermal resistivity is 2.22.

In its original condition it is a dark golden color but after expansion it generally becomes pale yellow.

As a loose fill. Vermiculite has already been extensively used as a loose fill for the insulation of roofs and is generally laid between joists of a thickness of 2 in. or 3 in. according to the degree of insulation required, in a house where the U value of the basic roof structure is 0.43 the addition of 2 in. of vermiculite fill between ceiling joists would make the U value 0.15, and 3 in. thick, 0.11.

Floor and roof screeds. The two forms in which Vermiculite is used as a concrete— that is mixed with cement and water—are as floor and roof screeds and as light weight blocks. These screeds in addition to possessing excellent thermal and sound insulation are extremely light in weight and of course entirely incombustible. In a floor where radiant heating pipes are being laid, these are placed on top of the Vermiculite screed before being embedded in dense concrete, thus ensuring the maximum transmission of heat to the room with the minimum downward loss. These screeds are normally laid 2 in. to 3 in. thick, and should not be less than 1 ¼ in. In order to provide a suitable surface on which the floor finish can be laid, the screeds are covered with a sand and cement topping to a minimum thickness of ¾ in. Vermiculite screeds do not require expansion joints. They can be used on a variety of roofs—flat, low pitched or barrel vault, and serve to conserve heat in the winter and keep buildings cool in the summer.

Light weight concrete blocks. Vermiculite has now been used for at least 10 years for light weight concrete blocks and slabs. It provides a valuable building material because in addition to its light weight it has high thermal insulation value. A restricting factor however has been the difficulty of large scale machine manufacture because hand production means labour costs are high and output limited. Developments however are being made in the production of block making machines which will produce Vermiculite building blocks at ч fairly high rate. The densities of most Vermiculite concrete blocks so far used vary from 27 lb. to 40 lb. a cu. ft., which demonstrates their lightness. They have a high fire resistance. Two inch blocks have a 4 hour rating for the protection of structural steel. The mix varies according to requirements but as in the case of floor and roof screeds it is in the ratio of 1 to 4 or 1 to 5. Being very light in weight the blocks are easy to handle even if they are of considerable size.

Vermiculite plaster. The other material with which Vermiculite has been used extensively is plaster both in the form of slabs and in-situ application. Vermiculite piaster has similar fire resisting and insulation properties to Vermiculite concrete. The range of density is 28 to 56 lb. per cu. ft. These Vermiculite plasters are produced in a wide variety, many of which have been tested for thermal conductivity, the range being 0.75 "K" for a density of 56 lb. per cu. ft. The value of using Vermiculite plaster can hardly be overemphasized because of its very high insulation value which combined with the low thermal capacity reduces the rate at which heat is lost through walls and ceilings and enables comfortable living and working temperatures to be reached quickly. Also the surface of Vermiculite plaster closely follows the temperature of the atmosphere and thus condensation is much reduced. It should be added that to get the best anti-condensation result the surface should not be too heavily toweled and the decorative finish should be permeable. This applies only to anti-condensation plasters. Absorbent paints and distempers are more suitable than oilbound paints.

REINFORCED CONCRETE

Reinforced concrete is a combination of two of the strongest structural materials, concrete and steel, either of which is used separately. Consequently, the resulting material has the advantages of both.

Concrete has poor elastic and tensional properties, but it is rigid, strong in compression, extremely durable under and above ground, and in the presence or absence of air and water, it increases in strength with age, it is fire resistant, and suitable for any architectural or engineering forms.

Steel has great tensional, compressive and elastic properties but is not durable below ground or if exposed to moisture, it loses its strength with age or exposure to high temperature. Steel is also fragile in appearance, giving an impression of weakness rather than strength. When strength is the most important consideration great care must be taken to produce a concrete that will be homogeneous and as dense as possible. Homogeneity is not possible without thorough mixing. To obtain strength and density, the aggregate must be sand and gravel, or crushed rock clean and free from organic matter, and carefully graded from the smallest to the largest particles.

The maximum size of the aggregate depends upon the thickness of the concrete and the closeness of the reinforcing steel.

For slabs up to three inches thick it should pass a half inch mesh, for slabs over three inches, and for beams, columns, footings retaining walls, and other moderately heavy work, it should not be more than three quarter inch, and from one to one and a half inch for heavy work. All that passes a three-sixteenth inch mesh should be considered sand.

The sand and stone must be proportioned and mixed so that all cavities formed between the various size particles can be completely filled with smaller particles down to cavities that can be filled only with cement.

The cement should be ground extremely fine and should be stored in a water-proof shed, or otherwise well protected from atmospheric influence.

The water should be fresh and free from earthy and organic matter. Sea water should not be used for reinforced work. The sodium chloride that it contains may oxidize the steel with resulting cracks in the concrete.

For general work the most suitable proportions of cement and aggregate are: 1 part cement, 2 parts sand, and 4 parts gravel or crushed rock.

Let us consider what is the effect of the addition of steel reinforcement to a concrete.

Steel is a material which does not undergo shrinkage on drying, and therefore the steel acts as a restraining medium in a reinforced concrete member; shrinkage causes tensile stresses in the concrete which are balanced by compressive stresses in the steel. Now the steel itself deforms under the induced stresses so that there must be a resultant shrinkage moment in a reinforced concrete member.

An economic quantity of steel, however, can be so disposed as to distribute the cracking under shrinkage stresses and thus render it innocuous. This is the problem for the designer of a reinforced concrete building, and it demands careful consideration on a proper design basis, both of the quantity and of the distribution of the reinforcement.

The method of reinforcement generally used is putting in a wire mesh or system of light rods into the concrete and that must not be done at random.

It may be stated here for reinforced walls the area of reinforcing steel should be not less than 0,1 per cent of the area, both horizontally and vertically.

Although it is preferable from theoretical consideration to use small rods at close spacing, constructional difficulties will often necessitate the use of larger bars at greater spacing. When this happens, it is desirable to increase somewhat the percentage of reinforcement.

In some cases the drying of the concrete may be expected to proceed at different rates, at the two faces, and in such cases it is reasonable to use different percentage of reinforcement at the two faces.

Owing to complex stress distribution round openings special treatment may be desirable at such points.

REINFORCED CONCRETE COLUMNS.

Reinforced concrete columns may be divided according to the method of reinforcement into:

· Columns with vertical bars only;

· Columns with structural steel core;

· Columns with cast-iron core.

The columns with structural steel and cast-iron cores may also be provided with spiral reinforcement.

Unsupported Length of Column.—The unsupported length of reinforced concrete columns shall be taken as:

(a) In flat slab construction, the clear distance between the floor and under side of the capital;

(b) In beam-and-slab construction, the clear distance between the floor and the under side of the shallowest beam framing into the column.at the next higher floor 1evel;

(c) In floor construction with beams in one direction only, the clear distance between floor slabs;

(d) In columns supported laterally by struts or beams only, the clear distance between consecutive pairs (or groups) of struts or beams, provided that to be considered an adequate support, two such struts or beams shall meet the column at approximately the same level and the angle between the two planes formed by the axis of the column and the axis of each strut, respectively, is not less than 75 degrees not more than 105 degrees.

When haunches are used at the junction of beams or struts with columns, the clear distance between supports may be considered as reduced by two-thirds of the depth of the haunch.

DETAILS OF COLUMNS WITH LONGITUDINAL STEEL ONLY

General Requirements. — Steel bars used for column reinforcement must be straight. They must be placed in vertical position and be prevented from displacement by hoops or ties. In square and rectangular columns, the bars should be arranged symmetrically. They should preferably be placed along the perimeter of the effective area. Since vertical bars, if properly imbedded and placed symmetrically, take their stress regardless of their location in the column, the effective area of the column (contrary to action in a spiral column) has no relation to the area of concrete located between the lines of steel. Thus, a requirement of 1 ½ in. of fireproofing does not mean that the steel bars must be placed within 1 ½ in. of the surface. On the contrary, the bars should be placed far enough away from the forms to give ample room for placing concrete. A minimum distance of 2 in. is recommended.

Sometimes, when a large number of bars is used and it is not possible to accommodate all of them along the perimeter, some bars are placed in the middle section of the column. This is not advisable, however, as the bars in the central part are hard to keep in place. They also interfere with the placing of the concrete.

To get a symmetrical arrangement, an even number of bars should be used in a square or rectangular column. It is preferable that all the bars used in a column be of the same diameter. In many instances this is not possible without considerable waste of steel. Then the column reinforcement is made up of two groups of bars (each consisting of an even number of bars for square or rectangular columns). The bars in the two groups should vary in diameter by not more than one-eighth in. Thus, to get an area of steel equal to 6.9 sq. in., five 7/8-in. round bars plus five 1-in. round bars may be used. To use ten 1-in. round bars would mean a waste of 3.13 lb. of steel per lineal foot of column, which for a large number-of columns may amount to a considerable tonnage. Seven 1-in. square bars give a close enough area and may be used in round columns. They cannot be used in square or rectangular columns, however, because it would not be possible to arrange them symmetrically.

There is one objection to using bars of different diameters in one column. Where experienced labor and good supervision are not available, there is danger that all small sizes may be used in one column and all large sizes in another. Under such conditions, bars of the same diameter should be used even if it means some waste of material.

At least four bars should be used per column. In good practice, the bars should be at least 5/8 in. rd. to give sufficient lateral strength to the columns to withstand any bending which may come on them, either by unequal loading or by some accidental horizontal pressure. In long buildings, the columns in the end row of panels are subjected to considerable bending due to temperature changes. The building lengthens or shortens from the middle toward the ends, so that the top of the end columns must deflect by an amount equal to the total expansion or contraction of one-half of the length of the building. The bending stresses produced thereby may be large, particularly in top columns. To prevent cracks, additional steel should be used.

When a large percentage of steel is used, it is advisable to use bars of large diameter so that the clear spacing along the perimeter between the bars is not smaller than 3 in. When the reinforcement of the column consists of very heavy bars, it is advisable, for practical reasons, to use at least four light bars.

BEAMS

Precast concrete floor units are at present manufactured mainly in the following different types:

a) ribbed slabs or channel units;

b) beams of hollow core type;

c) I-beam section, with either cast-in-place or precast slab;

d) inverted I-beam joists with lightweight filler blocks between;

e) beams assembled from hollow concrete blocks;

f) precast and prestressed floor units.

Channel Beam.—The type most frequently used in industrial building, warehouses, etc., where a plain ceiling is not required. The main reinforcement is usually one bottom bar per rib; top reinforcement for erection for purpose, one single bar of approximately 0,5-in. diameter over each web; stirrups in cross stiffeners, 0,25-in. diameter bars bent into rectangular shape.

For sites where heavy erection equipment is available, several of the channel types are precast in one wider beam with several ribs. The advantage of this is quicker erection and a reduction in the quantity of concrete, its disadvantage being that such units are not so suitable for continuity reinforcement.

Hollow Beam.—The hollow beam with a box cross section gives a smooth and plain ceiling finish immediately after erection. The width of these units varies between 10 in. and 2 ft., and the depth between 6 in. and 1 ft. 3 in., according to span and superload. The reinforcement is placed at the bottom of the side walls, the thickness of which varies between 1 and 1,5 in. The bottom flange is usually ¾ in. thick, the top flange between 1,5 and 2,5 in., according to span and loading conditions. Its weight is between 40 and 60 lb. per sq. ft. On the external sides there are sloped grooves providing for a better connection with the neighboring units when the joints are filled in with cement mortar. Because of the plain ceiling, hollow beams are used mostly for dwellings, offices, and such public buildings as schools and hospitals. Channel beams are lighter in weight, easier to manufacture and cheaper.

An important feature in the production of hollow beams is the use of inflated rubber tubes which make dismantling quick, easy, and safe.

I-section.—There are several methods of forming I-shaped joists. In most of them, all reinforcing bars are assembled in advance to form a reinforcing "cage". The shear rods are welded to the moment bars top and bottom. The moment bars vary from two 3/8 in. diameter top and bottom in the 3-in. by 8-in. joist, to two 1-in. diameter in the 4 in. by 14-in. joist. The shear rods are generally round, welded in between the moment bars, making a space between the moment bars. From the manufacturing standpoint this is ideal, since the size of the shear-bars may be kept constant and their spacing can be varied according to the need for shear reinforcing. The reinforcement in these joists is well anchored because of the welded connection between web and main steel.

T-section. — The Т type is most simple to manufacture, being cast with the flange inverted on the shop floor. But this section should only be applied to roof structures, or to floors in dwellings, etc., where heavy local superloads are never to be expected. For, although the small mortars joint between the top flanges of the two neighboring sections might secure an equal deformation of loaded and unloaded members at the designed load, it will crack long before the critical load is reached; at that stage each of the loaded members is detached from the other, and there is no cross distribution of the loads.

There are several kinds of concrete floors. Which is used depends upon the class of building and the comparative costs, and advantages of the different kinds. The most simple to design, and generally the most economical, is the plain flat slab and beam system. In many buildings, however, it is desirable to keep the ceilings free of projecting beams; in such cases beamless systems are required. Where beams are not objected to, it is usual to plan the floors so that as many beams as possible will come over partition walls. With large spans between the beams the slabs generally work out to an excessive thickness and are therefore, heavy and costly. In such cases a lighter form of construction is desirable, and is generally obtained by adopting:

1. A rib and tile slab,

2. A rib, or concrete joists, slab; sometimes called a pan floor,

3. The flat slab system.

Both (1) and (2) can be finished with a plaster ceiling, in (1) the plaster is rendered directly upon the tile, in (2) metal lath is fixed to the joist by suspenders being embedded in the concrete.

The strength of slabs is determined in a similar manner to that of beams, and if they are supported or fixed, at two opposite sides only, the bending moment will be the same as for a beam similarly supported or fixed; but with a slab supported, or fixed, at all four sides the bending moment will not be so great as that for a beam of the same span, owing to the slab being strengthened by the supports at the ends as well as at the sides. A square slab supported on all four sides is twice as strong as the same slab supported on two opposite sides only: this ratio, however, varies as the length increases, the reaction of the side supports becoming greater than that of the ends, until the length exceeds about twice its width when the reaction of the end supports can be ignored as the effect of this reaction on the strength of the slab is too slight to be considered. Consequently, the slab may then be considered as a simple beam of length equal to 'the width of the slab.

In a square slab the fractures follow the diagonals thus making an angle of 45 degrees with the ends, but as the slab increases in length the lines of fracture make a smaller angle with the ends.

Consequently, with a square slab, the supports are equally loaded, and as the length increase the load on the side support increases and that on the ends decreases.

Список использованных источников:

1. И.П.Агабекян, П.И.Коваленко. Английский для технических вузов. Ростов н/Д: «Феникс», 2002. – 352с.

2. Л.Н.Андрианова, Н.Ю.Багрова, Э.В.Ершова. Курс английского языка для вечерних и заочных технических вузов. – М.: Высшая школа, 2001.–464 с.

3. Электронная энциклопедия «Британника 2001».

2020-05-25

2020-05-25 159

159