MINISTRY OF EDUCATION AND SCIENCE OF UKRAINE

National Aviation University

HYDRAULICS

Course work for students

Kyiv 2013

PREFACE

The extensive use of hydraulics and pneumatics to transmit power is determined by the fact that properly designed Fluid power systems possess a number of favorable advantages. The different parts of a Fluid power system can be conveniently located at widely separated points, since the forces generated are rapidly transmitted over considerable distances with small loss. Hydraulic systems should be particularly useful because of their fast response and their great stiffness as seen by the load.

“Hydraulics” provides the methods of calculating and designing a wide range of hydraulic structures, machinery and other devices used in different technique branches (especially in transport). Modern aircraft design relies on the science of hydraulics.

The study of “Hydraulics” is directed to the behavior of a fluid in hydraulic drives, fuel and lubricating systems, hydraulic shock absorbers and many other applications of Fluid power.

The purpose of this term paper is to consolidate and systematize the knowledge obtained in the process of studying “Hydraulics”, to learn how to design typical hydrogas systems and also to get skills of self-training and working with technical literature. It would be useful for further diploma work preparation.

The methodical guide contains 10 assignments and 10 variants of numerical values to each schematic diagram.

References

1.B.NEKRASOV. Hydraulics for Aeronautical Engineers. - M: Mir Publishers, 1969. -275p.

2.V.BOCHAROV, V.BOUTKO. Hydraulics. Methodical instructions for laboratory works. - Kyiv, NAU, 2003. -40p.

ASSIGNMENT 1

Fig.1. Schematic diagram of the fuel system: 1 – service tanks; 2 – fuel pump; 3 – non-return valve; 4 – filter; 5 – booster pump

Booster centrifugal pump (Fig.1.) supplies kerosene T-1 to the fuel pump from two tanks located at heights of h1 and h2.

Absolute pressure in tanks is Pt1 and Pt2, absolute pressure at booster pump entrance is Pb. p.. Volumes of pendant tanks are W1 and W2 , liquid viscosity coefficient is n and density is r. Local resistances, set in the pipelines, are shown in the schematic diagram of a fuel system under consideration.

Determine:

1. Pipelines diameters d1 and d2, considering that the tanks evacuation would be finished simultaneously at a given pump delivery Q.

2. Required pressure head of the pump 5. A pipeline length from booster

3. to fuel pump is l3, its diameter is d3, required pressure at the fuel pump entrance is P1.

4. Consumed power of the pump, when its total efficiency is η.

Calculation data should be taken from the table 1.

Note. Liquid head in the tank should be ignored.

Solution technique:

1. Determine the fuel consumption from each tank, using given data of W1 and W2, Q.

2. Compute kerosene flow velocity in the pipeline, Re-number and resistance coefficient, using random diameter range for d1 and d2.

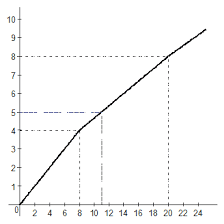

3. Determine required pressure head Hreq for each of diameters and plot the curve of function Hreq= f (d1). The values of local resistance coefficients should be taken from [1].

Table1

| DATA | Variant | |||||||||

| QQ, m3 /s | 0,0005 | 0,0008 | 0,001 | 0,0012 | 0,0014 | 0,0016 | 0,0018 | 0,002 | 0,0022 | 0,0024 |

| W1, m3 | ||||||||||

| W2, m3 | 0,5 | 1,5 | 3,5 | 4,0 | 3,5 | 6,5 | ||||

| P1, kPa | ||||||||||

| Pt1, kPa | ||||||||||

| Pt2, kPa | ||||||||||

| H1, m | 2,5 | 3,5 | 3,8 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0 | ||

| H2, m | 0,75 | 2,5 | 2,4 | 2,6 | 2,8 | |||||

| H3, m | 0,5 | 1,5 | 2,5 | 3,5 | 4,5 | |||||

| L1, m | 2,5 | 3,6 | 4,2 | 5,2 | 6,0 | 6,4 | 6,8 | |||

| l 2, m | 1,8 | 2,6 | 3,2 | 3,4 | 4,4 | 5,6 | 6,2 | 6,6 | 7,5 | |

| Pbp, kPa | ||||||||||

| L3, m | 1,2 | 1,8 | 2,8 | 3,5 | 4,2 | 4,8 | 5,2 | |||

| D3, m | 0,012 | 0,014 | 0,016 | 0,018 | 0,02 | 0,022 | 0,024 | 0,026 | 0,028 | 0,03 |

| γ, N/m3 | ||||||||||

| ν*10-6 m2/s | ||||||||||

| Η | 0,75 | 0,78 | 0,8 | 0,82 | 0,84 | 0,8 | 0,75 | 0,7 | 0,84 | 0,76 |

4. Obtain d1, d2 using the available pressure head and choose the standard ones.

5. Determine the flow velocity of liquid V, Re-number and resistance coefficient λ, using assigned supply data Q and pipeline diameter d3.

6. Estimate head losses between the booster and the fuel pumps.

7. Using assigned data of Hreq and Pbp, determine consumed power of the pump.

2015-08-21

2015-08-21 593

593