While the specification concludes with claims defining the features of the invention that are regarded as novel, it is believed that the invention will be better understood from a consideration of the description of exemplary embodiments in conjunction with the drawings. It is of course to be understood that the embodiments described herein are merely exemplary of the invention, which can be embodied in various forms. Therefore, specific structural and functional details disclosed in relation to the exemplary embodiments described herein are not to be interpreted as limiting, but merely as a representative basis for teaching one skilled in the art to variously employ the present invention in virtually any appropriate form. Furthermore, the terms and phrases used herein are not intended to be limiting but rather to provide an understandable description of the invention.

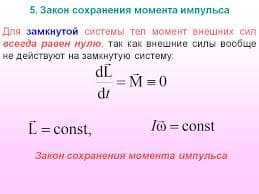

As shown in the exemplary embodiment illustrated in Figure 1, dispersant molecules 12 are utilized to prevent soot and other particulates 10 from agglomerating by keeping the particles suspended and thereby lessening risk they pose to engine parts. Dispersants typically consist of a non-metallic polymer with a polar end (consisting of, for example, oxygen or nitrogen) having a high affinity for soot and a nonpolar, oil-soluble tail (such as a hydrocarbon). Examples of dispersants include substituted and polyamine succinamides, polyhydroxy succinic esters, polybutene hydroxy benzyl polyamines, and copolymers of polymethacryaltes and styrenemaleinic esters. Each dispersant type has a different binding affinity for soot particles. Referring now to Figure 2, an exemplary embodiment of a process for regenerating used dispersant incorporated into lubricating oil in accordance with the present invention is illustrated. Exemplary process 100 begins at step 110 with the used dispersant suspending particulate matter in the lubricating oil. At step 120, the used lubricating oil, having dispersant molecules suspending particulate matter (for example, soot formed from operation of a diesel engine), is supplied into a regenerating chamber, where the dispersant will be regenerated. This can be done, for instance, by pumping the oil into the regeneration chamber using an oil pump that is powered by the vehicle's engine.

|

|

|

At step 130, the suspended particulate matter is released from the dispersant molecules by creating a stress on the bond between the dispersant molecules and the particulate matter. This can be done, for instance, by increasing the temperature within the regeneration chamber if the type of dispersant used has a high enthalpy. Auxiliary regeneration additives, such as elements from the transition metals (for example, cerium, iron, copper, strontium, and platinum), can also be included in the lubricating oil to depress the energy required to break the particulate-dispersant bond. The heat can be supplied by, for instance, power from the vehicle's onboard electrical system that warms the regeneration chamber to the appropriate temperature, thus permitting well-controlled regeneration of the dispersant.

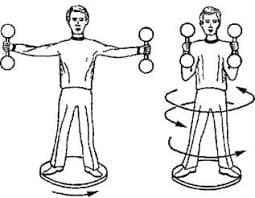

Once the bond between the particulate matter and the dispersant is broken, at step 140, the released particulate matter can be permitted to agglomerate. As shown in the exemplary embodiment illustrated in Figure 3, because of the high surface energy of the particulate matter, the agglomeration will proceed relatively rapidly and the particulates 10 will grow in size.

Once the particulate matter has agglomerated, the agglomerated particulate matter is removed from the lubricating oil at step 150 Because the particle size of the particulate matter will be larger at this step, conventional filtration or centrifugation can be used to separate and remove the particulate matter. At this point, the present exemplary process has regenerated the dispersant in the lubricating oil by removing or substantially reducing the particulate matter, thereby substantially restoring the dispersing ability of the dispersant to its original level. At step 160, the regenerated lubricating oil can be discharged back to the engine using, for instance, the oil pump or a light phase outlet of the regeneration chamber, where the free dispersant will continue to capture particulate matter and prevent agglomeration.

Referring now to Figure 4, an alternative exemplary embodiment of a process for regenerating used dispersant incorporated into lubricating oil in accordance with the present invention is illustrated. Exemplary process 200, which utilizes phase separation, begins at step 210 with the used dispersant suspending particulate matter in the lubricating oil. At step 220, the used lubricating oil, having dispersant molecules suspending particulate matter (for example, soot formed from operation of a diesel engine), is supplied to a capturing chamber, where the dispersant will be regenerated. This can be done, for instance, by pumping the oil into the capturing chamber using an oil pump powered by the vehicle engine.

|

|

|

At step 230, the used lubricating oil is caused to interact with an oil-insoluble capturing composition. The capturing composition has a binding affinity for the particulate matter that is greater than that of the polar ends of the non-metallic dispersant polymer molecules. The capturing composition can be, for instance, disposed on a surface of fibrous media or included as part of a solvent phase within the capturing chamber.

In exemplary, non-limiting embodiments in which the capturing composition employed at step 230 is disposed on a surface of fibrous media, the media can be incorporated in a filter system. The fibrous media intercepts the particulate the matter through inertial forces and retains the particulates through chemical binding. The filter system can involve stand-still regeneration or exchangeable filters that are regenerated through combustion of the captured particulate matter, and then disposed of and replaced at the end of the life-cycle of the system.

In exemplary, non-limiting embodiments in which the capturing composition employed at step 230 is included as part of a solvent phase within the capturing chamber, the dispersant is not soluble in the displacing solvent, and the displacing solvent is not be soluble in oil. For a sufficiently high- degree of impaction to facilitate the chemical reaction of the step, the immiscible oil and solvent phases should be mixed until equilibrium is reached. Because the dispersant is insoluble in the solvent, the particulate matter will be displaced from the dispersant in the lubricating oil and extracted into the solvent phase. Once this ion transfer is complete, the solvent, which now carries the particulate matter, and the oil, which contains the dispersant that is now free of particulate matter, are permitted to separate. For better dispersant recovery, the lubricating oil, in exemplary embodiments, can be sequentially mixed with two equal volumes or several smaller volumes of solvent rather than with all the solvent in one large volume.

In other exemplary, non-limiting embodiments in which the capturing composition employed at step 230 is included as part of a solvent phase within the capturing chamber, a phase transfer catalyst for capturing the particulate matter can be utilized. In these exemplary embodiments, the capturing catalyst can be immobilized on a fiber surface through which the lubricating oil is filtered. During filtration, the particulate matter is displaced from the dispersant in the lubricating oil and reacts to bond with the catalyst. As a result of the reaction, the particulate matter becomes soluble in the solvent phase, which enables the particulate matter to be separated from the oil and move into the solvent phase, thereby freeing the dispersant molecules, which remain in the oil.

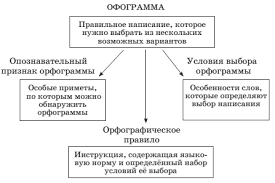

The interaction that takes place step 230 causes, at step 240, a chemical reaction within the capturing chamber in which the suspended particulate matter is displaced from the dispersant molecules and binds to the capturing composition (for example, the particulate matter can be bound to a capture surface or within a solvent phase). The operation of displacement and binding can be seen in the exemplary reaction illustrated in Figures 5A-D. In Figure 5 A, the dispersant molecules 12 have suspended particulate 10 In Figures 5B and 5 C, the lubricating oil is interacted with the capturing composition 14, and particulate 10 is displaced from dispersant 12 In Figure 5D, particulate 10 binds to capturing composition 14, and dispersant 12 is free. During this step, is the dispersant should be chemically and physically stable in the presence of the capturing mechanism so that it can be recycled through many times without experiencing undue physical loss or chemical breakdown. Further, the extraction and displacement kinetics should be sufficiently fast to allow the process to take place in an acceptable time frame.

At this point in exemplary process 200, the dispersant in the lubricating oil has been regenerated by having the particulate matter that had been suspended therein removed or substantially reduced, thereby substantially restoring the dispersing ability of the dispersant to its original level. The lubricating oil can then, at step 250, be discharged back to the engine using, for instance, the oil pump or a light phase outlet of the regeneration chamber, where the free dispersant can capture particulate matter and prevent agglomeration.

CLAIMS

What is claimed is:

1.A method of regenerating used dispersant incorporated into lubricating oil, comprising the steps of: supplying used lubricating oil having dispersant molecules suspending particulate matter into a regenerating chamber; releasing the particulate matter by creating a stress on the bond between the dispersant molecules and the suspended particulate matter; permitting the released particulate matter to agglomerate; removing the agglomerated particulate matter from the lubricating oil; and discharging the lubricating oil back to the engine.

2.The method according to claim 1, wherein the particulate matter comprises diesel engine soot.

3.The method according to claims 1 or 2, wherein the dispersant is selected from the group consisting of substituted and polyamine succinamides, polyhydroxy succinic esters, polybutene hydroxy benzyl polyamines, and copolymers of polymethacryaltes and styrenemaleinic esters.

4.The method according to any of the claims 1 to 3, wherein the lubricating oil further

comprises an auxiliary regeneration additive.

5.The method according to any of the claims 1 to 4, wherein the agglomerated particulate

matter is removed from the lubricating oil with a centrifuge.

6.The method according to any of the claims 1 to 4, wherein the agglomerated particulate

matter is removed from the lubricating oil by filtration.

7.The method according to any of the claims 1 to 6, wherein an increase in temperature

within the regenerating chamber creates the stress on the bond between the dispersant

molecules and the suspended particulate matter.

8.A method of regenerating used dispersant incorporated into lubricating oil, comprising the steps of: supplying used lubricating oil having non-metallic polymer dispersant molecules suspending particulate matter into a capturing chamber, the dispersant molecules having polar ends and non-polar tails; interacting the used lubricating oil with an oil-insoluble capturing composition having a binding affinity for the particulate matter that is greater than that of the polar ends of the dispersant molecules to displace the suspended particulate matter and bind the particulate matter to the capturing composition within the capturing chamber; and discharging the lubricating oil back to the engine.

|

|

|

9.The method according to claim 8, wherein the particulate matter comprises diesel engine soot.

10. The method according to claims 8 or 9, wherein the dispersant is selected from the group consisting of substituted and polyamine succinamides, polyhydroxy succinic esters, polybutene hydroxy benzyl polyamines, and copolymers of polymethacryaltes and styrenemaleinic esters.

11. The method according to any of the claims 8 to 10, wherein the capturing composition is disposed on a surface of fibrous media within the capturing chamber.

12. The method according to any of the claims 9 to 11, wherein the capturing composition within the capturing chamber comprises a solvent phase.

13. The method according to any of the claims 8 to 12, wherein solvent phase comprises two contiguous stages having equal volumes of solvent with which the lubricating oil is sequentially mixed.

14. The method according to any of the claims 8 to 13, wherein solvent phase comprises several contiguous stages having smaller volumes of solvent with which the lubricating oil is sequentially mixed.

2020-04-07

2020-04-07 141

141